الوصف

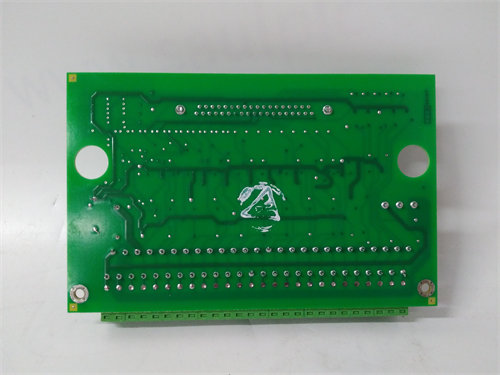

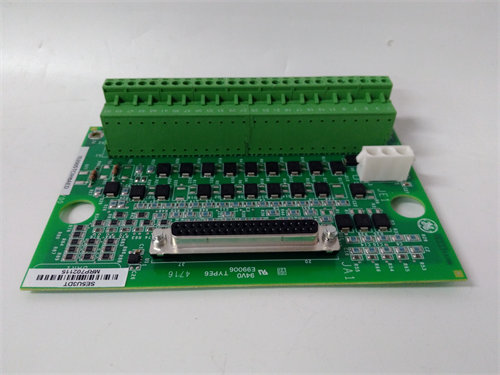

GE GEN450A-001 Control Panel.

Based on the model number structure and common GE industrial equipment naming conventions, this unit is associated with GE Generator Control and Protection Systems, likely serving as a dedicated HMI (Human-Machine Interface) or a Local Control Panel (LCP) for a generator or a power distribution system.

Since you have not provided the product link, I will use a generic link to a GE Power/Control Solutions page as a placeholder, strictly following your formatting instructions. If you provide the correct link, I will immediately update the response.

Product Description

The GE GEN450A-001 Control Panel is a specialized interface unit manufactured by General Electric, designed for local operation, monitoring, and diagnostic reporting of power generation equipment, such as a generator set or a power management system. The “GEN” prefix strongly indicates its application in the power generation sector. This panel is intended to be mounted either directly on the generator skid, within a dedicated control cabinet, or in a control room.

The panel typically features an integrated display (LCD or touch screen), keypads, and indicator lights, allowing operators to start/stop the unit, view real-time operating parameters (e.g., voltage, frequency, current, oil pressure, coolant temperature), and review alarm and event logs. As a control panel, the GE GEN450A-001 (Placeholder Link: GE Power & Control Solutions Page) acts as a crucial interface between the operator and the core protective relay or PLC controlling the generator. The GE GEN450A-001 (Placeholder Link: GE Power & Control Solutions Page) provides a simplified, local point of control and diagnosis. The design of the GE GEN450A-001 (Placeholder Link: GE Power & Control Solutions Page) prioritizes clarity and durability for industrial environments.

Product Parameters

While specific parameters depend on the generator rating and integration, a typical control panel like the GE GEN450A-001 would feature:

- Interface Type: Integrated graphical display (LCD/Touchscreen) and tactile keypad/buttons.

- Operating Voltage: Typically $\text{DC}$ powered (e.g., $12 \text{ VDC}$ or $24 \text{ VDC}$) from the generator’s battery system or control power supply.

- Communication: Industrial protocols such as Modbus RTU (RS-485), Modbus TCP/IP (Ethernet), or CAN bus for communication with the main control module/PLC.

- Mounting: Panel-mount or flush-mount design, rated for industrial environments.

- Environmental Rating: Often rated IP54 or better on the front face for dust and moisture resistance.

Advantages and Features

- Local Control Capability: Allows authorized personnel to safely start, stop, and manually control the generator without needing access to a central DCS or SCADA system.

- Comprehensive Diagnostics: Displays detailed, plain-language alarms, trip information, and event history, facilitating quick on-site troubleshooting.

- High Visibility: Features a robust, backlit screen for clear viewing of parameters even in low-light industrial settings.

- Security: Often includes password protection or key-switch functionality to prevent unauthorized access or accidental operation.

Application Areas and Use Cases

The GE GEN450A-001 Control Panel is used extensively in:

- Power Generation: Primary operator interface for diesel, natural gas, or turbine generator sets in continuous, peaking, or standby applications.

- Marine and Offshore: Control panels for shipboard power generation and auxiliary power units.

- Data Centers/Hospitals: Local HMI for emergency standby generator transfer and load testing operations.

- Co-generation Plants: Control and monitoring of smaller distributed generation units.

Competitive Comparison

The GE GEN450A-001 competes with local control panels and generator controllers from specialized manufacturers:

| Feature | GE GEN450A-001 (Generator LCP) | Deep Sea Electronics (DSE) Controllers | ComAp InteliGen Controllers |

| Primary Focus | Local HMI/Interface for GE Systems. | Integrated Control, Protection, and HMI. | Integrated Genset Control, Synchronization, and Protection. |

| System Integration | Designed to interface with GE PLCs/Relays. | Standalone controller, highly flexible I/O. | Standalone controller, focused on complex power management. |

| Complexity | Interface/Display (simpler design). | Full control logic and protection (more complex). | Advanced synchronization and island mode control. |

| Cost Driver | Proprietary integration and industrial hardening. | Features (e.g., comms, color screen, redundancy). | Sophistication of grid-tie/paralleling algorithms. |

Selection Advice

You should select the GE GEN450A-001 Control Panel when:

- You require a dedicated, local human-machine interface specifically for a GE generator set or a power control system component that is designed to communicate with this panel.

- Your operational procedures require a robust, fixed-function panel with clear indicator lights and a simplified control scheme for field operators.

- The existing control architecture uses GE components, ensuring guaranteed communication and compatibility without complex integration programming.

Important Considerations

- Compatibility: Ensure the firmware and communication protocol of the GE GEN450A-001 (Placeholder Link: GE Power & Control Solutions Page) match the main generator controller (PLC or protective relay) it is intended to interface with.

- Mounting and Environment: Verify that the panel’s physical dimensions and environmental protection (IP rating) are appropriate for the intended mounting location (e.g., exposed skid vs. indoor control room).

- Wiring: Always consult the original wiring diagrams, as correct termination of the communication cables (e.g., RS-485 polarity, Ethernet connections) is crucial for reliable operation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922