الوصف

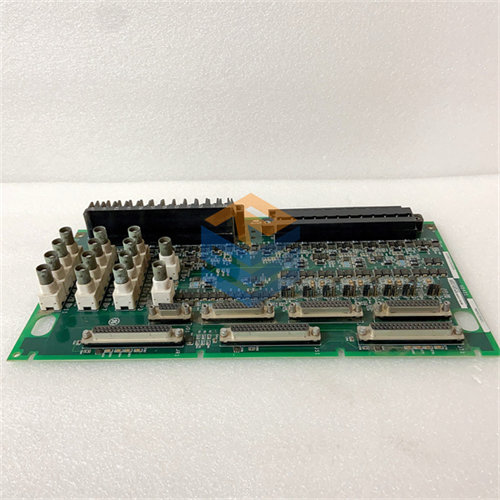

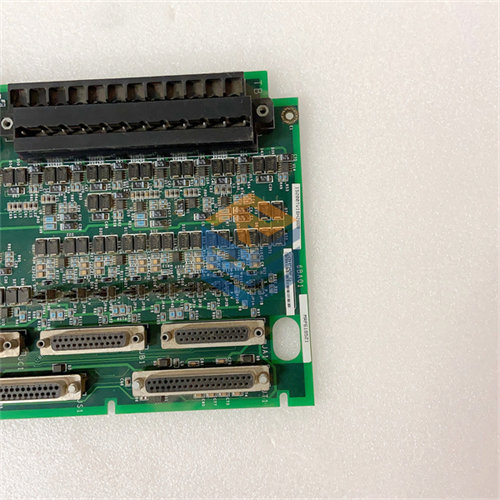

The GE part number IC3600SSVG1 is a Servo Valve Drive Card. This specialized electronic circuit board is a component of GE’s legacy Mark I and Mark II series of turbine control systems. Its primary function is to precisely control the position of a servo valve, which in turn regulates the flow of fluid (such as fuel or steam) to the turbine.

Function and Key Features

A servo valve drive card like the IC3600SSVG1 is a crucial component of a closed-loop control system. It receives a low-level command signal from the main turbine controller and converts it into a high-power electrical signal to drive a servo actuator. The card constantly monitors the actual position of the actuator via a feedback sensor (like an LVDT) and adjusts its output to ensure the actuator’s position matches the command signal.

- Signal Conversion and Amplification: It converts various input signals (analog, digital, or PWM) into the necessary electrical signals to drive the servo valve, providing the required current and voltage.

- Precision Control: It provides the high-precision control necessary to operate critical turbine components, such as fuel or steam valves. This precise control is essential for maintaining stable speed and load.

- Closed-Loop System: It forms a feedback loop by comparing the desired position with the actual position and making continuous corrections. This ensures a high degree of accuracy and rapid response.

- Protection Mechanisms: It includes safeguards like overcurrent, overvoltage, and short-circuit protection to prevent damage and ensure safe operation.

- Robust Design: Built for harsh industrial environments, it’s designed to withstand vibrations, temperature fluctuations, and electromagnetic interference.

Applications

The IC3600SSVG1 is a legacy component, so it is primarily used in power generation facilities that still operate GE’s older Mark I and Mark II turbine control systems. It is an essential component for:

- Turbine Control: It is used to precisely control the position of governor valves, stop valves, and other actuators that regulate the flow of fuel or steam to the turbine.

- Load and Speed Regulation: By controlling the flow of the working fluid, the card helps to regulate the turbine’s speed and electrical output, which is crucial for maintaining grid stability.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922