الوصف

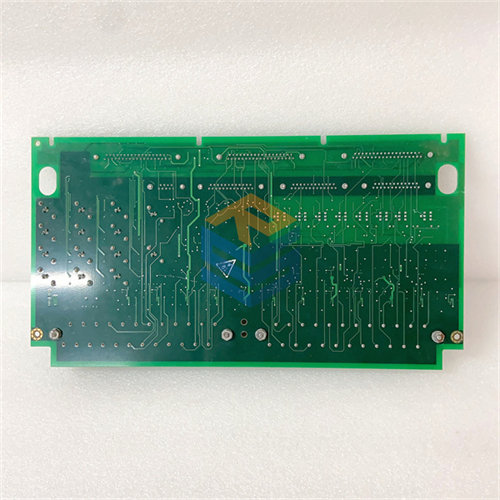

The GE part number IC3603A278F is a Thermocouple Processing Module. It was manufactured for GE’s legacy Speedtronic Mark I and Mark II series turbine control systems. Its primary function is to accurately process and condition the low-level electrical signals from thermocouples, making them usable for the turbine’s control and protection systems. 🌡️

Function and Key Features

A thermocouple is a type of sensor that measures temperature. It generates a very small voltage that corresponds to temperature. The raw signal from a thermocouple is often noisy and difficult to use directly. The IC3603A278F card’s job is to handle this signal effectively.

- Signal Processing: The card takes the low-voltage, analog signal from the thermocouple and amplifies and linearizes it. This process converts the raw signal into a clean, scaled output that the main controller can interpret as a precise temperature.

- Noise Reduction: Power plants are electrically noisy environments. The card includes filtering to remove electrical interference that could corrupt the temperature readings, ensuring the accuracy and reliability of the data.

- Cold-Junction Compensation: For accurate temperature measurement, a thermocouple requires a reference temperature, known as the “cold junction.” The IC3603A278F provides this compensation, allowing the system to accurately determine the temperature at the sensing point.

- Robust Design: Like all GE industrial control boards, it’s built to withstand the harsh conditions of a power plant, including vibrations, temperature fluctuations, and electromagnetic interference.

Applications

The IC3603A278F is a legacy component, so it is primarily used in power generation facilities that still operate GE’s older Mark I and Mark II turbine control systems. It is an essential component for:

- Turbine Temperature Control: It provides a critical input for the turbine’s temperature control loop, ensuring that the turbine operates within safe temperature limits to prevent overheating.

- Safety and Protection: Accurate temperature monitoring is vital for safety. The card contributes to the overall safety system by providing the data needed to trigger alarms or emergency shutdowns in over-temperature conditions.

- Performance Monitoring: By providing accurate temperature data, the card helps operators and engineers monitor the turbine’s performance and efficiency.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922