الوصف

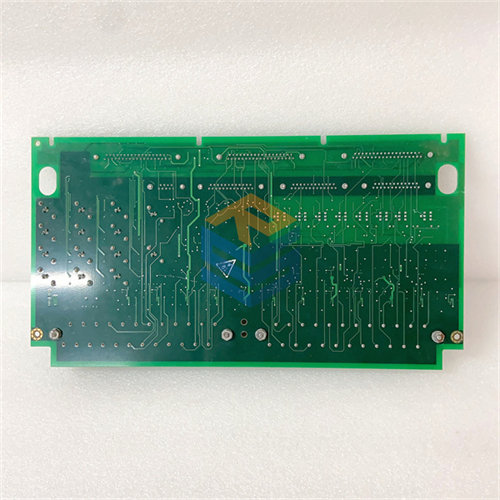

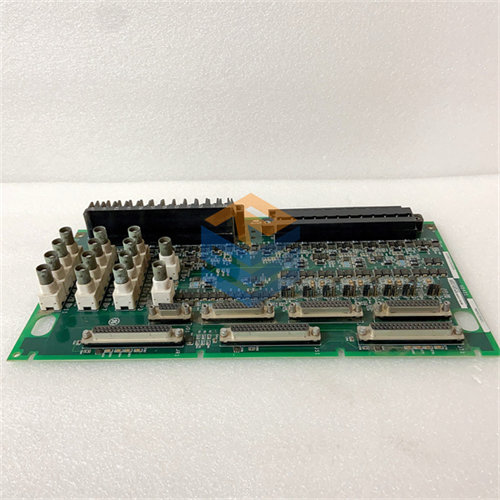

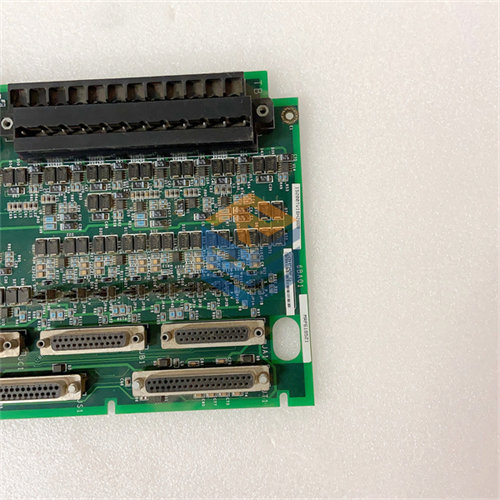

The GE part number IC3606STML1 is a Thermocouple Averaging Switch Assembly. This unit is a key component of GE’s legacy Speedtronic Mark I and Mark II series of turbine control systems. Its primary function is to manage and average the signals from multiple thermocouples to provide a single, reliable temperature reading for the control system. 🌡️

Function and Key Features

In large turbines, multiple thermocouples are often placed in the same area (e.g., the exhaust gas path) to ensure more accurate and reliable temperature measurement. The IC3606STML1 assembly is designed to handle this task with both averaging and switching capabilities.

- Signal Averaging: The assembly receives analog signals from a set of thermocouples and calculates their average value. This is a crucial function because it helps to smooth out minor temperature fluctuations and provides a more stable and representative input for the control system.

- Switching Function: In addition to averaging, the assembly can also have a switching function. This allows the control system to either average the signals or switch to a single thermocouple reading, for example, for diagnostic purposes or in case one of the sensors is faulty.

- Redundancy: By averaging and switching between signals, the assembly provides a high degree of redundancy. If one of the thermocouples fails, the system can still operate using the remaining sensors, preventing a false alarm or a unnecessary shutdown.

- Signal Conditioning: The assembly also conditions the low-level millivolt signals from the thermocouples, amplifying and filtering them to remove electrical noise and make them usable for the main control and protection circuits.

- Robust Design: Like all GE industrial control components, it’s built to withstand the harsh conditions of a power plant, including vibrations, temperature fluctuations, and electromagnetic interference.

Applications

The IC3606STML1 is a legacy component, so it is primarily used in power generation facilities that still operate GE’s older Mark I and Mark II turbine control systems. It is an essential component for:

- Turbine Temperature Monitoring: It provides an accurate and reliable input for the turbine’s temperature control loop, ensuring that the turbine operates within safe temperature limits.

- Safety Systems: The averaged temperature reading is crucial for the safety system, which can trigger an alarm or emergency shutdown if the temperature exceeds a set limit.

The GE part number IC3606STML1 is a Thermocouple Averaging Switch Assembly. This unit is a key component of GE’s legacy Speedtronic Mark I and Mark II series of turbine control systems. Its primary function is to manage and average the signals from multiple thermocouples to provide a single, reliable temperature reading for the control system. 🌡️

Function and Key Features

In large turbines, multiple thermocouples are often placed in the same area (e.g., the exhaust gas path) to ensure more accurate and reliable temperature measurement. The IC3606STML1 assembly is designed to handle this task with both averaging and switching capabilities.

- Signal Averaging: The assembly receives analog signals from a set of thermocouples and calculates their average value. This is a crucial function because it helps to smooth out minor temperature fluctuations and provides a more stable and representative input for the control system.

- Switching Function: In addition to averaging, the assembly can also have a switching function. This allows the control system to either average the signals or switch to a single thermocouple reading, for example, for diagnostic purposes or in case one of the sensors is faulty.

- Redundancy: By averaging and switching between signals, the assembly provides a high degree of redundancy. If one of the thermocouples fails, the system can still operate using the remaining sensors, preventing a false alarm or a unnecessary shutdown.

- Signal Conditioning: The assembly also conditions the low-level millivolt signals from the thermocouples, amplifying and filtering them to remove electrical noise and make them usable for the main control and protection circuits.

- Robust Design: Like all GE industrial control components, it’s built to withstand the harsh conditions of a power plant, including vibrations, temperature fluctuations, and electromagnetic interference.

Applications

The IC3606STML1 is a legacy component, so it is primarily used in power generation facilities that still operate GE’s older Mark I and Mark II turbine control systems. It is an essential component for:

- Turbine Temperature Monitoring: It provides an accurate and reliable input for the turbine’s temperature control loop, ensuring that the turbine operates within safe temperature limits.

- Safety Systems: The averaged temperature reading is crucial for the safety system, which can trigger an alarm or emergency shutdown if the temperature exceeds a set limit.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922