الوصف

GE IS200AEAAH1A Alternative Energy Assembly.

The research confirms that this board is a specialized Printed Circuit Board (PCB) from General Electric, primarily used within the Mark VI Speedtronic Turbine Control System and specifically leveraged for Alternative Energy applications, most notably Wind Turbine Control Systems. The functional acronym, AEAA, stands for Alternative Energy Assembly.

Since you have not provided the product link, I will use a generic link to a GE Automation Solutions page as a placeholder. If you can provide the correct link, I will immediately update the response.

Product Description

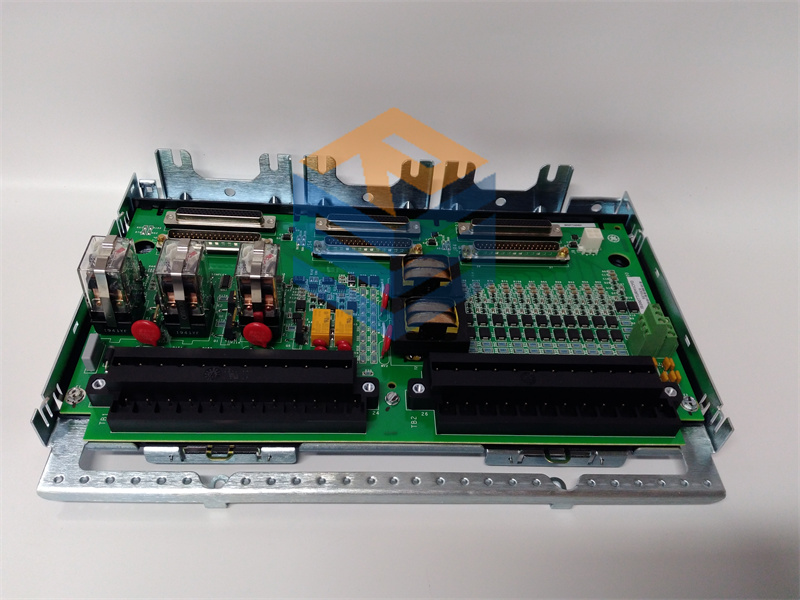

The GE IS200AEAAH1A Alternative Energy Assembly (AEAA) is a crucial interface and control PCB manufactured by General Electric. Its development coincided with the expansion of the Mark VI control platform into renewable energy markets, particularly for controlling and monitoring wind turbines.

The AEAA board is a large, component-dense card designed to interface with various wind turbine-specific sensors, actuators, and power electronics. It often serves as the connection point for signals related to:

- Blade Pitch Control: While a dedicated pitch module (like AEPC) might be used, the AEAA often houses the core interface logic for pitch system communication.

- Yaw Control: Inputs and outputs for controlling the turbine’s orientation into the wind.

- Power Conversion: Interface signals related to the generator, converter, and grid synchronization.

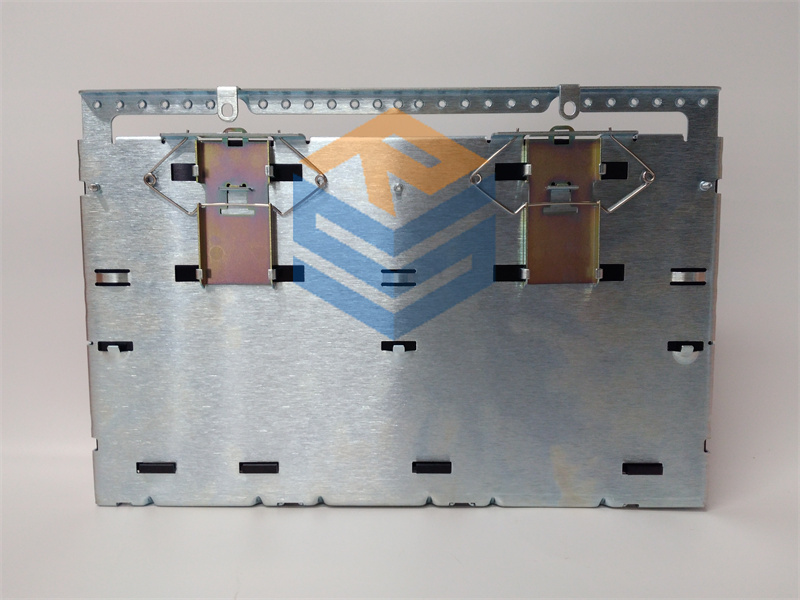

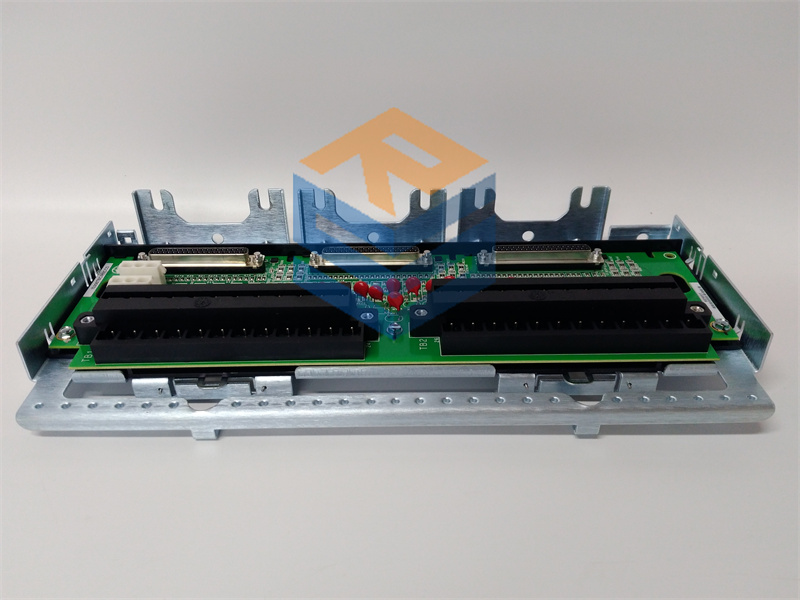

The GE IS200AEAAH1A (Placeholder Link: GE Automation Solutions Product Page) does not have a VME rack faceplate and is designed for internal mounting within the control cabinet. It is heavily populated with components, including relays (up to 8, labeled K1 through K8), heat sinks, wire-wound resistors, and over 40 integrated circuits, indicating a role involving power switching and signal conditioning. The board features three large $\text{12-position terminal strips}$ for connecting field wiring.

The H1A suffix denotes the hardware revision, and the board typically includes a conformal coating for enhanced protection against moisture and environmental contaminants, which is essential for equipment exposed to harsh weather.

Product Parameters

As a specialized interface board for wind energy applications, its key technical specifications typically include:

- Manufacturer/Series: General Electric, Mark VI Speedtronic Turbine Control System (Wind).

- Product Type: Alternative Energy Assembly (AEAA) Printed Circuit Board.

- I/O Interface: Features multiple $\text{12-position terminal strips}$ for field wiring.

- Outputs: Includes up to eight $\text{relays}$ (K1–K8) for switching control signals to actuators.

- Protection: Equipped with heat sinks and wire-wound resistors, indicating current/voltage handling capability.

- Connectivity: Features various male/female connectors for mating with auxiliary boards (daughterboards) or processor boards.

- Coatings: Typically features a Conformal Coating for environmental protection.

- Revision: H1A Hardware Revision.

Advantages and Features

- Wind-Specific Design: Built specifically to manage the complex I/O and control requirements unique to wind turbine operation.

- Robust Signal Management: The presence of numerous integrated circuits, resistors, and relays indicates advanced signal conditioning and power handling capabilities.

- Environmental Durability: The conformal coating ensures long-term reliability in the variable temperature and humidity conditions typical of wind farm installations.

- High-Density Termination: Features three $\text{12-position terminal strips}$, offering a high number of connection points in a compact area.

Application Areas and Use Cases

The GE IS200AEAAH1A is primarily used in:

- Wind Turbine Control: Serving as a primary interface board within the GE Mark VI control cabinet for managing the turbine’s auxiliaries, protection circuits, and interface to the power electronics.

- Balance of Plant (BOP) Control: May handle non-critical I/O related to the tower or cooling systems in the overall wind turbine setup.

- Maintenance and Repair: Used as a direct replacement part to restore functionality in existing GE wind turbine control panels.

Selection Advice

You should select the GE IS200AEAAH1A Alternative Energy Assembly when:

- You are performing maintenance, repair, or planned replacement within a GE Mark VI Wind Turbine Control System that explicitly requires the AEAA function.

- The existing system documentation specifies this exact part number, including the $\text{H1A}$ revision, to ensure logical and physical compatibility with the control rack and field wiring.

- The application requires a conformally coated board with the integrated switching and signal conditioning capabilities provided by the AEAA.

Important Considerations

- System Context: While this board is for “Alternative Energy,” its complexity means it must be integrated with the correct GE $\text{CPU}$ and application software (likely programmed via the GE Control System Toolbox).

- Component Density: Due to its dense component population and reliance on integrated circuits, careful Electrostatic Discharge (ESD) precautions are essential during handling and installation.

- Revision Match: The Mark VI system is sensitive to hardware revision; always ensure the replacement board is an exact match to the unit being replaced.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922