الوصف

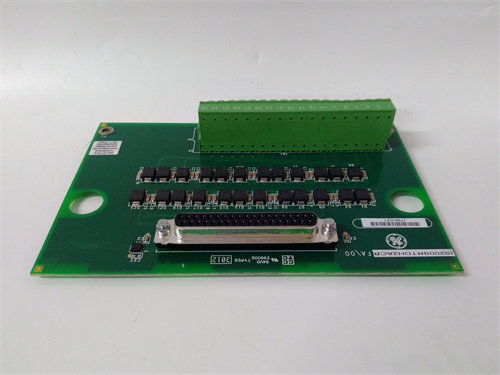

The GE IS200AEAAH1CPR is a specific revision of a highly specialized Printed Circuit Board (PCB) known as the Alternative Energy Assembly (AEAA), manufactured by General Electric for their Mark VI Speedtronic Turbine Control System.1

This board is a key I/O and interface module used to manage the complex control and monitoring of auxiliary systems, particularly those associated with alternative energy applications like wind turbine control, where the Mark VI platform is often deployed.

The specific suffixes in the part number indicate both the hardware configuration and environmental protection:

- AEAA (Alternative Energy Assembly): This functional acronym defines its role as an interface for diverse I/O, often involving switching and signal conditioning for non-core turbine control elements.2

- H1C: Designates a specific hardware and firmware revision. The ‘C’ often implies the presence of a Conformal Coating for enhanced protection against moisture, dust, and corrosive environments.3

- PR: The trailing two letters usually denote a specific Production Release or a Repair/Refurbished tag, further specifying the board’s origin or revision level.

🛠️ Key Technical Specifications

The IS200AEAAH1CPR is a complex PCB with significant on-board components, giving it advanced switching and signal management capabilities:

- Manufacturer/Series: General Electric, Mark VI Speedtronic Control System.4

- Functional Role: Advanced I/O and Interface Board for Auxiliary/Alternative Energy Control.

- Component Density: High, including over 40 integrated circuits, various resistors, capacitors, and multiple specialized connectors.5

- Switching Capacity: Features up to eight on-board relays (6$\text{K1}$ through 7$\text{K8}$) for power switching and control of field actuators.8

- Field Interface: Typically includes three parallel terminal strips, each with twelve positions, for high-density, secure field wiring connections.9

- Mounting: Designed as a “Normal Assembly” PCB for internal mounting within a control cabinet (not a VME rack faceplate).10

- Environmental Protection: The ‘C’ and ‘H’ suffixes often confirm a Conformal Coating layer is applied to the board for increased environmental durability.11

⚙️ Primary Application and Function

The AEAA board acts as the versatile connection and logic point for systems requiring specialized electrical interface or switching:

- Wind Turbine Control: Manages I/O for systems like blade pitch control, yaw drives, and signals related to the generator and power conversion equipment.

- Auxiliary Turbine Control: Handles I/O for balance of plant (BOP) equipment, like large pumps, cooling systems, or emergency brake mechanisms that operate outside the core turbine control loops.

- Signal Conditioning: Its dense circuitry conditions and processes various field signals before they are communicated to the main Mark VI control processor.

⚠️ Important Considerations for Selection

- Revision Match: The full part number, including the H1CPR suffix, is crucial. GE Mark VI systems are highly sensitive to revision matching; using a board with a different suffix can lead to configuration errors or system incompatibility.

- Environment: The conformal coating makes this a suitable choice for applications in humid, dusty, or chemically harsh environments, such as those found in wind farms or industrial power plants.

- Replacement: This board is typically used as a direct replacement part to maintain the operational status of an existing Mark VI system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922