الوصف

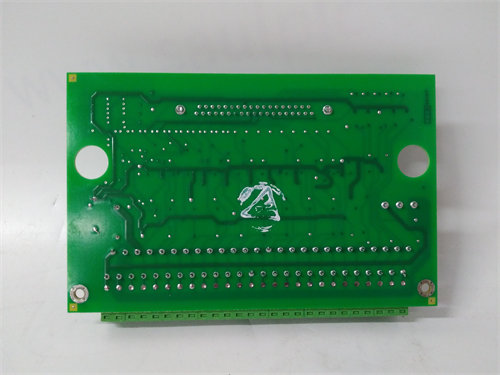

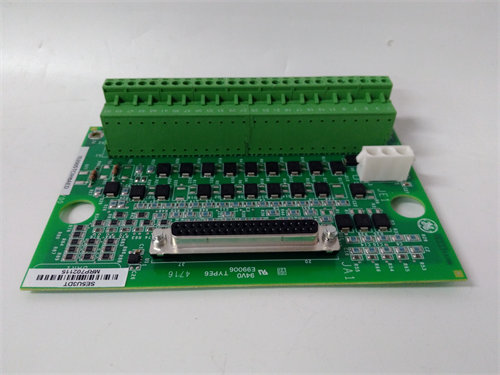

The GE IS200AEAAH1CPR1 is a highly specific revision of a critical Printed Circuit Board (PCB) component within General Electric’s Speedtronic Mark VI Turbine Control System.1

While you refer to it as a “Gas Turbine Control Board,” the functional acronym AEAA stands for Alternative Energy Assembly, which gives it a specialized role, typically managing auxiliary or non-core turbine functions, often associated with wind power or the balance-of-plant (BOP) I/O in a conventional gas turbine system.

⚙️ Product Profile: IS200AEAAH1CPR1

The IS200AEAAH1CPR1 is an advanced I/O and interface board designed for high-reliability industrial control.2 The specific part number provides a wealth of information:

| Part Segment | Meaning | Detail |

| IS200 | Board Series | Indicates a “Normal Assembly” PCB design for internal cabinet mounting, part of the Mark VI system. |

| AEAA | Functional Acronym | Alternative Energy Assembly. This board is designed for specialized I/O, often found in wind turbine control or complex turbine auxiliary systems. |

| H | Technology Code | Indicates the presence of Surface-Mount Technology (SMT) components, signifying a modern, high-density design. |

| 1 | Assembly Variant | Denotes the first major variant of the AEAA board design. |

| C | Environmental Code | Usually indicates the presence of Conformal Coating for protection against moisture, dust, and corrosive environments. |

| PR1 | Revision/Release | Denotes a specific Production Release (PR) and the R1 is the unique artwork configuration or sub-revision level. This specificity is crucial for replacement. |

🛠️ Key Technical Features and Function

The AEAA board is a component-dense module built to handle switching and signal conditioning for various field devices:

- Integrated Switching: The board is equipped with up to eight on-board relays (3$\text{K1}$ through 4$\text{K8}$).5 These relays are used to control field actuators, such as those for yaw control, pitch mechanisms, or cooling systems.

- High-Density I/O: It features three parallel terminal strips, each typically having twelve positions, offering a high volume of secure connection points for field wiring.6

- Signal Conditioning: The board contains over 40 integrated circuits, along with resistors and capacitors, which condition and process signals from the field before they are transmitted to the main Mark VI control processor.7

- Environmental Robustness: The ‘C’ and ‘H’ in the part number confirm its design for industrial environments, particularly with the conformal coating making it suitable for wind farm or outdoor applications where humidity and contaminants are an issue.

🏭 Application in Gas Turbine Systems

While the name suggests “Alternative Energy,” in a gas turbine context, the IS200AEAAH1CPR1 is commonly used for:

- Auxiliary Control: Managing non-core, but important, equipment (Balance of Plant or BOP) that requires dedicated switching and monitoring.

- Specialized I/O: Interfacing with unique sensors or actuators that fall outside the standard I/O boards (like $\text{TRPH}$ or $\text{TURL}$).

⚠️ Important Considerations

- Revision Match is Critical: The H1CPR1 suffix is extremely specific. When replacing this board, you must use a matching revision to ensure compatibility with the system’s firmware and control software (ControlST/Control System Toolbox). Incompatible revisions can cause control failures.

- Handling: Due to the high number of integrated circuits, strict Electrostatic Discharge (ESD) handling procedures must be followed during installation or removal.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922