الوصف

GE IS200AEBIH1B is a specialized Printed Circuit Board (PCB) designed as an AE Bridge Interface within the General Electric Mark VI Speedtronic Turbine Control System series.1

Despite the general “Bridge Interface” name, the functional acronym AEBI (Alternative Energy Bridge Interface) points to a highly specific role in GE’s control architecture.2

⚙️ Product Profile: IS200AEBIH1B

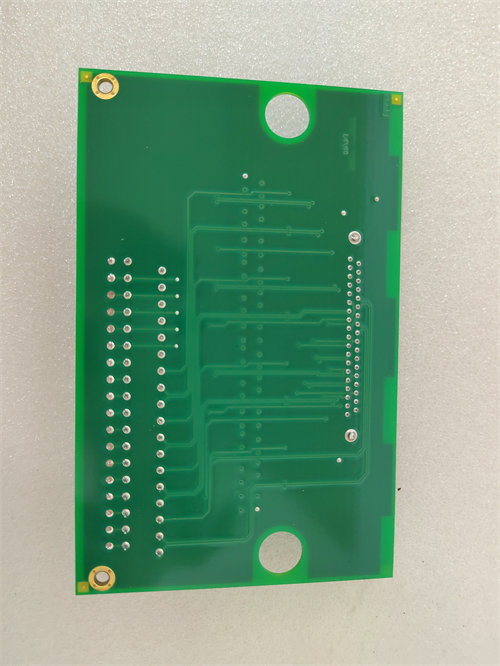

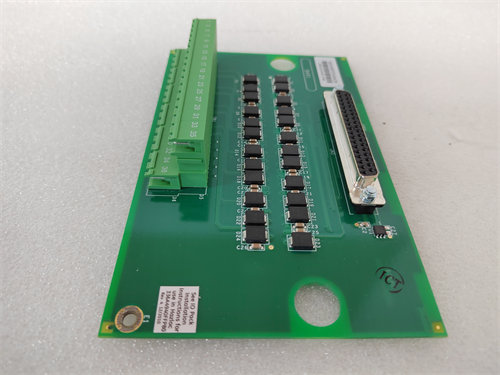

This board is part of the IS200 series, indicating it is a “Normal Assembly” PCB designed for mounting inside the control cabinet, distinct from VME-style boards.

| Part Segment | Meaning | Detail |

| IS200 | Board Series | Component within the GE Mark VI Speedtronic System. |

| AEBI | Functional Acronym | Alternative Energy Bridge Interface. This role is typically in wind turbine control or complex turbine auxiliary systems. |

| H1 | Assembly Variant | Denotes the hardware version utilizing Surface-Mount Technology (SMT). |

| B | Revision | Specifies the exact functional revision level (B-rated). Crucial for compatibility. |

🛠️ Key Technical Features and Function

The IS200AEBIH1B serves as a vital communication and signal bridge to integrate specialized or high-speed auxiliary systems—particularly those related to alternative energy or motor drives—into the main Mark VI controller.3

- Bridge Function: It acts as an interface that takes signals from a specific subsystem (likely a drive or a localized control module) and translates/conditions them for communication with the main Mark VI processor. The term “bridge” often implies a connection between two different protocols or hardware interfaces.

- Target Application: It was manufactured by GE Energy specifically for use in wind turbine control systems, which were an application added to the Mark VI series.4 It is vital for proper turbine operations and communications in this subseries.

- Component Density: A visual inspection reveals a component-dense PCB with:

- Over 200 resistors and over 200 capacitors for signal regulation and conditioning.5

- Numerous integrated circuits organized in groups.

- Multiple ports, labeled with standard “P” nomenclature.6

- Environmental Protection: The board is known to be conformally coated for enhanced protection against moisture, dust, and corrosive elements, which is essential for equipment used in exposed industrial environments like wind farms.7

- System Integration: It utilizes the standard Mark VI series tools, including CIMPLICITY graphics and the Control System Toolbox, for maintenance, configuration, and monitoring.8

⚠️ Important Considerations for Replacement

- Revision Match: The H1B revision is highly specific. When replacing this board, it is absolutely critical to use a board with the exact matching revision to ensure compatibility with the system’s loaded firmware and control logic.

- Documentation: Detailed functional information, including jumper settings and pinouts, is often restricted to the original GE Instructional Manuals (GEI-series).9 This documentation is necessary for safe and correct installation.

- Handling: Due to its density of integrated circuits, strict Electrostatic Discharge (ESD) handling procedures must be observed at all times.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922