الوصف

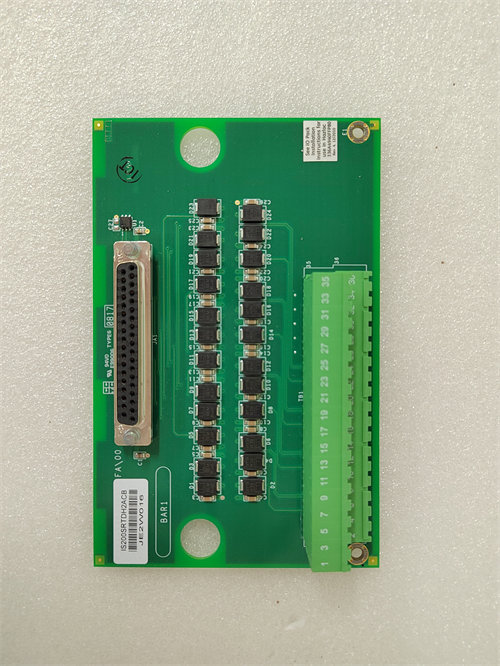

The GE IS200AEPAH1AAA is a highly specialized Printed Circuit Board (PCB) from the General Electric Mark VI Speedtronic Turbine Control System series. Its functional acronym, AEPA, stands for Alternative Energy Pitch Axis, indicating a critical role in wind turbine control systems.

This board is an advanced I/O module designed to manage the numerous inputs and outputs required for precise control of wind turbine blades (pitch axis control) and other complex auxiliary functions.

⚙️ Product Profile and Function

The IS200AEPAH1AAA is a standard assembly PCB (part of the IS200 series) that connects to the main Mark VI controller. It serves as a single-board interface with high-density I/O specific to the wind turbine application.

| Parameter | Specification/Detail |

| Functional Acronym | AEPA (Alternative Energy Pitch Axis) |

| Primary Function | I/O and Control for Wind Turbine Pitch Axis (blade control) |

| System Family | GE Mark VI (or Mark VIe Wind) Speedtronic Control |

| Redundancy Support | Compatible with Simplex, Dual, or Triple Modular Redundant (TMR) architectures. |

| Environmental Protection | Includes Conformal Coating for protection against moisture and contaminants. |

| Revision | H1AAA—This highly specific revision is crucial for compatibility. |

🛠️ Key Technical Features

The AEPA board is notable for its extensive and varied I/O capabilities, all integrated onto one module for the complex demands of pitch control:

- Inputs & Outputs: The board is densely populated, providing a mix of signal types:

- Analog Inputs (AI): Typically 8 inputs (e.g., for monitoring temperature, voltage, pressure).

- Discrete Inputs (DI): Typically 20 inputs (e.g., for limit switches and protective signals).

- Relay Outputs (RO): Typically 8 relays (for switching external loads, alarms, or motors).

- Analog Output (AO): Typically 1 output (for sending control references).

- Encoder Inputs: Supports both 1 Incremental Encoder and 1 Absolute Encoder input for precise position and speed feedback from the pitch mechanism.

- Brake Control Output: Features 1 dedicated output for managing the braking system.

- Auxiliary Connectivity: The board is designed to interface with an optional auxiliary board (daughterboard) via two plug connectors in the upper left corner, enhancing its functionality.

- Surge Protection: Includes several Metal Oxide Varistors (MOVs) for crucial surge protection.

- Communication: Communicates with the main Mark VI controller via internal connectors and supports standard system protocols like IONet and Unit Data Highway (UDH).

⚠️ Important Considerations for Replacement

- Revision Match: The IS200AEPAH1AAA must be replaced with a board of the exact same revision (H1AAA) or a known compatible replacement specified by GE. Mismatched revisions can cause major control system failures due to incompatible firmware or signal scaling.

- Application-Specific: This board’s I/O is highly specific to the pitch axis control of a wind turbine. It is not a general-purpose I/O module and cannot be substituted for other Mark VI boards without extensive configuration changes.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922