الوصف

GE IS200AEPAH1AFD is a highly specific Printed Circuit Board (PCB) component manufactured by General Electric for the Mark VI Speedtronic Turbine Control System series.1

Its functional acronym, AEPA, stands for Alternative Energy Pitch Axis, which clearly defines its role as a critical I/O and Interface module primarily used for wind turbine control systems.2

⚙️ Product Profile and Function

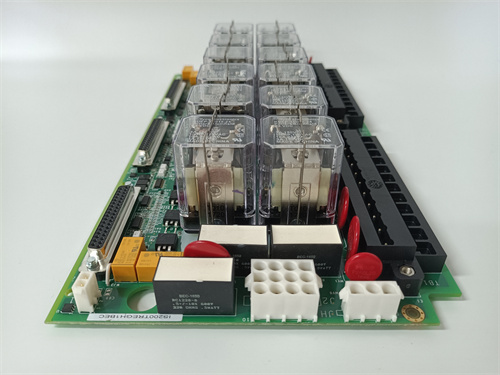

The IS200AEPAH1AFD is a non-VME, or “Normal Assembly,” board designed for internal mounting within the Mark VI control cabinet. It acts as the central interface for all signals related to the precise, real-time positioning of the turbine blades (pitch control), as well as other high-density auxiliary I/O.

| Parameter | Specification/Detail |

| Functional Acronym | AEPA (Alternative Energy Pitch Axis) |

| Primary Function | High-Density I/O Interface for wind turbine pitch control systems and general auxiliary control. |

| System Family | GE Mark VI (or Mark VIe Wind) Speedtronic Control. |

| I/O Capabilities | Supports a mix of signals: Analog Inputs (8), Discrete Inputs (20), Relay Outputs (8), and dedicated inputs for Incremental and Absolute Encoders (essential for pitch position feedback). |

| Communication | Uses protocols like IONet and Unit Data Highway (UDH) to communicate with the main processor. |

| Redundancy | Compatible with Simplex, Dual, and Triple Modular Redundant (TMR) architectures. |

| Environmental Code | The full code, including the ‘A’ and ‘F’ designations, specifies the exact hardware and firmware revision, often including Conformal Coating for environmental protection. |

🛠️ Key Technical Features

The complexity of the AEPA board’s I/O is necessary to manage the sophisticated control loops of modern wind turbines, particularly for pitch control:

- Precision Feedback: It integrates inputs for both Incremental and Absolute Encoders, allowing the controller to receive high-accuracy data on the current position and speed of the blade pitch mechanisms.

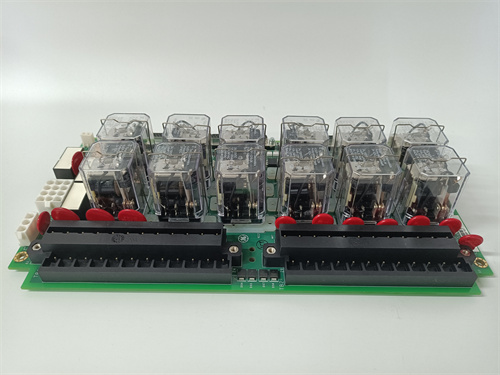

- Integrated Switching: It features up to eight Relay Outputs for controlling actuators, solenoids, or other high-load switching requirements for pitch, yaw, or brake systems.3

- Modularity: The board is designed to connect to an optional auxiliary board (daughterboard) via dedicated pin connectors, allowing for enhanced or customized functionality.4

- Robust Protection: It is typically built with Metal Oxide Varistors (MOVs) for surge protection and a Conformal Coating for protection against moisture and contaminants, which are common in wind turbine operating environments.5

⚠️ Important Considerations for Replacement

- Revision Match is Crucial: The suffix H1AFD is a specific production revision. Due to the critical, real-time nature of pitch control and the sensitive firmware of the Mark VI system, you must replace the board with an exact matching revision or one explicitly specified by GE as a direct substitute.

- Application-Specific: This is not a general-purpose I/O module. Its functions are tightly integrated with the physics and control algorithms of the turbine’s Pitch Axis and related auxiliary systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922