الوصف

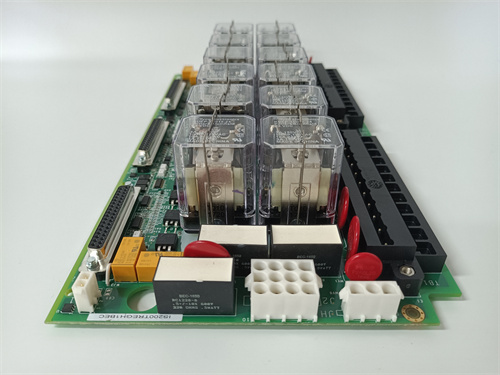

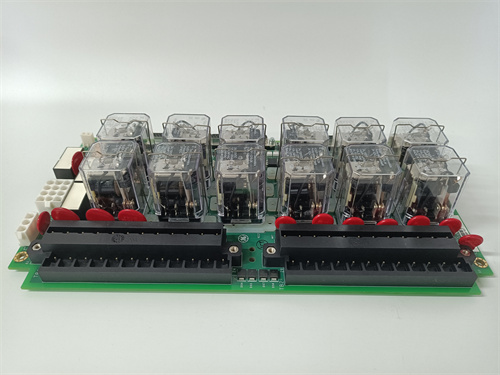

The GE IS200AEPCH1ABC is a specialized Printed Circuit Board (PCB) component from the General Electric Mark VI Speedtronic Turbine Control System series, primarily known as the Alternative Energy Pitch Center Module.1

This board is a critical control and communication interface designed specifically for managing the blade pitch control system of wind turbines.2 It is not a general-purpose I/O board, but one tailored for the complex, real-time demands of controlling turbine blade angles.

⚙️ Key Product Specifications

The IS200AEPCH1ABC is an IS200 series “Normal Assembly” board, meaning it is a rectangular PCB mounted internally within the control cabinet, usually with an auxiliary or daughterboard attached to its center.3

| Parameter | Detail |

| Functional Acronym | AEPC (Alternative Energy Pitch Center Module) |

| Primary Application | Wind Turbine Blade Pitch Control (ensures optimal power output and safety shutdowns). |

| System Family | GE Mark VI Speedtronic Turbine Control System. |

| Power Input | Typically requires a 24V DC, 8A power input. |

| Communication | Features an RS-422 interface for reliable data communication, likely to the pitch system’s local motor drive. |

| Design | Rectangular card without a faceplate. Includes a factory-mounted auxiliary/daughterboard populated with FPGAs and integrated circuits. |

| Environmental Code | The full code, including the ‘C’ at the end, usually confirms the presence of Conformal Coating for protection against moisture and contaminants. |

| Revision | H1ABC—This specific revision is essential for replacement compatibility. |

🛠️ Function and Control Role

The AEPC board’s primary role is to execute and manage the intricate pitch control algorithms necessary for a wind turbine’s operation:

- Real-Time Actuation: It takes digital commands from the main Mark VI processor and interfaces with the motor drives or hydraulic actuators that physically rotate the turbine blades.

- Safety and Optimization: Pitch control is a critical safety function, ensuring the blades can be quickly “feathered” (turned out of the wind) during overspeed conditions or high winds to prevent catastrophic failure. It also continuously adjusts the blade angle to maintain optimal aerodynamic efficiency for maximum power generation.4

- Integrated Components: The dense circuitry, often including FPGAs (Field-Programmable Gate Arrays) on the mounted daughterboard, performs the high-speed logic and processing required for precise pitch control.5

⚠️ Important Considerations for Replacement

- Revision Match is Critical: The suffix H1ABC is a specific production and firmware release. You must match this revision exactly when replacing the board. Substituting with a different revision may lead to severe compatibility issues, incorrect signal scaling, and failure of a critical turbine safety system.

- Auxiliary Board: Ensure any replacement or repair includes the correctly configured auxiliary or daughterboard, as much of the core pitch control functionality resides on this secondary component.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922