الوصف

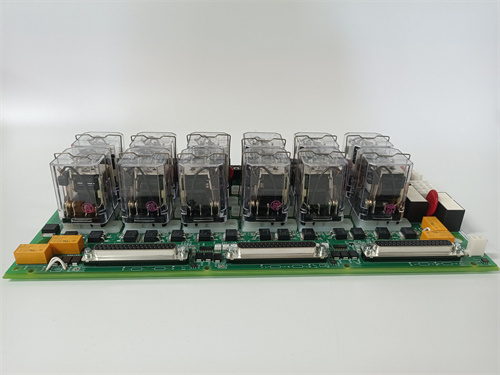

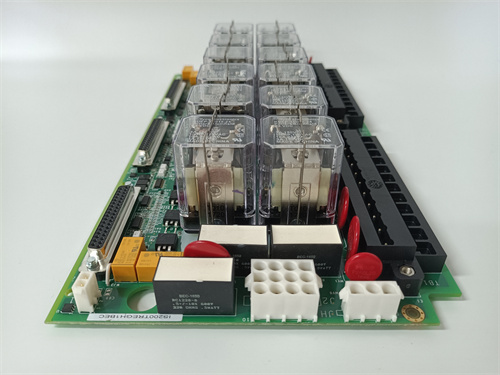

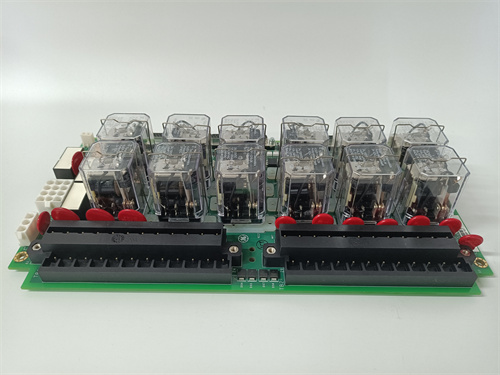

The GE IS200BAIAH1BEE is a highly specific Printed Circuit Board (PCB) known as the Bridge Application Interface Board (1$\text{BAIA}$).2 It’s a critical, multi-function interface card used in General Electric’s Mark VI Speedtronic Turbine Control System and its associated Innovation Series Drive assemblies.3

Its primary function is to serve as a communication, isolation, and signal conditioning bridge between the main digital processor ($\text{DSPX}$ board) and the external field wiring and user interfaces.

⚙️ Product Profile and Core Function

The $\text{BAIA}$ board is a VME-style card designed for vertical installation into a dedicated slot (usually Slot 1) within the control rack. The suffix H1BEE denotes a precise, late-stage hardware and firmware revision, which is crucial for compatibility.

Key Features:

- Signal Isolation: The board provides electrical isolation and an earth-ground reference for all signal inputs coming from external terminal boards.4 This protects the sensitive, low-voltage control electronics from industrial noise and ground potential differences.

- Communication Interface: It includes an RS-232C I/O interface, serving as the communication link between the main processor (5$\text{DSPX}$) and the drive system’s keypad and PC connections for diagnostics and configuration.6

- Analog I/O:

- It converts digital inputs from the $\text{DSPX}$ board into analog outputs (e.g., for panel meters or analog feedback).

- It supports two configurable bipolar ($\pm 10 \text{V}$) analog input channels.

- Configurability: It features multiple jumpers that allow field technicians to configure the analog inputs to accept either a voltage input (7$\text{VIN}$) or a 8$4-20 \text{ mA}$ (current input) signal, ensuring flexibility for different field sensors.9

- Discrete I/O: The board includes three Form C relays for discrete output switching and features several isolated, differential discrete logic inputs.10

⚠️ Important Considerations for Replacement

- Revision Match is Crucial: The suffix H1BEE is extremely specific. Given the board’s role in signal isolation, scaling, and communication protocol, you must match this revision exactly when sourcing a replacement. An incompatible revision risks communication failures, improper signal interpretation, and potential damage to the control system.

- Slot Restriction: The $\text{BAIA}$ board typically has a warning label stating, “Install in Slot 1 only,” within the VME rack. Adhering to this is mandatory to prevent damage to the board and the backplane.

- Handling: Due to the dense concentration of sensitive integrated circuits, handle the board only while observing strict Electrostatic Discharge ($\text{ESD}$) procedures.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922