الوصف

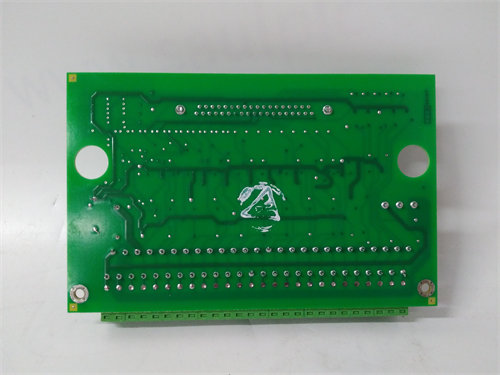

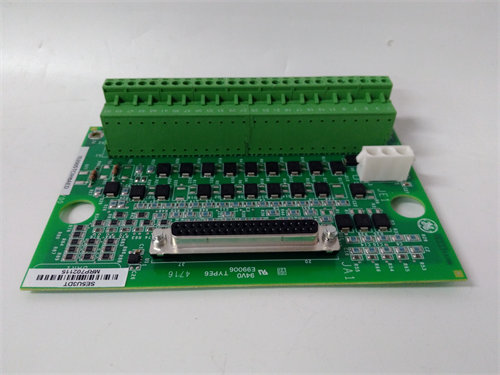

The GE IS200BICIH1AEC is a highly specialized Printed Circuit Board (PCB) known as a Bridge Interface Controller Board (1$\text{BICI}$).2 It is a key module within the General Electric Mark VI Speedtronic Turbine Control System and is often used in conjunction with integrated Drive Control Systems.

This board is a high-performance, specialized interface primarily focused on signal processing, isolation, and advanced control for complex auxiliary systems, particularly those that require sophisticated drive control logic and fast signal comparison.

⚙️ Key Technical Features and Function

The IS200BICIH1AEC is a critical interface that connects the main Mark VI control processor to demanding field devices. The detailed suffix H1AEC denotes a precise, later-stage hardware and firmware revision.

- Advanced Control Processing: The board is highly sophisticated and utilizes specialized integrated circuits to manage complex analog and digital signal handling. It often features specialized modules like:

- AOCA (Analog Comparator) modules: Used to provide independent, precise comparator circuits for fast protection and control logic.

- DVAA (Dual Voltage Controlled Oscillator) modules:3 Used for precise timing, frequency control, and pulse-train voltage output, essential for drive applications.

- Bridge and Drive Interface: The $\text{BICI}$ board often acts as a co-processor interface for the main $\text{DSPX}$ board, providing local intelligence to manage complex field processes. It is explicitly designed to interface with advanced power electronics, such as large industrial drives using IGCTs (Integrated Gate Commutated Thyristors).

- Signal Isolation and Conditioning: The board provides crucial electrical isolation between the low-voltage control circuitry and the high-voltage field wiring, protecting sensitive electronics. It uses dense circuitry (ICs, transistors, resistors) for accurate signal scaling and noise filtering.

- Connectivity and I/O: It typically includes specialized connectors ($\text{PFBK1}$, $\text{PFBK2}$, $\text{PSRC}$) that are vital for drive function and power feedback signals, along with diagnostics like an $\text{IMOK}$ LED to indicate operational status.

- Configuration: Some versions include user-configurable jumpers for selecting input ranges (voltage vs. current) or other operational modes, which must be set correctly upon replacement.

⚠️ Important Considerations for Replacement

- Revision Match is Critical: The H1AEC suffix must be matched exactly when sourcing a replacement. Given the board’s role in high-speed drive control, an incompatible revision risks catastrophic control failures, incorrect signal interpretation, or damage to the drive system components.

- Internal Modules: The $\text{BICI}$ board often relies on factory-soldered or fixed daughterboards (AOCA and DVAA types) for its specialized functionality. Any replacement must include these modules in their correct configuration.

- Handling: Due to its density of sensitive integrated circuits, observe strict Electrostatic Discharge ($\text{ESD}$) procedures during handling and installation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922