الوصف

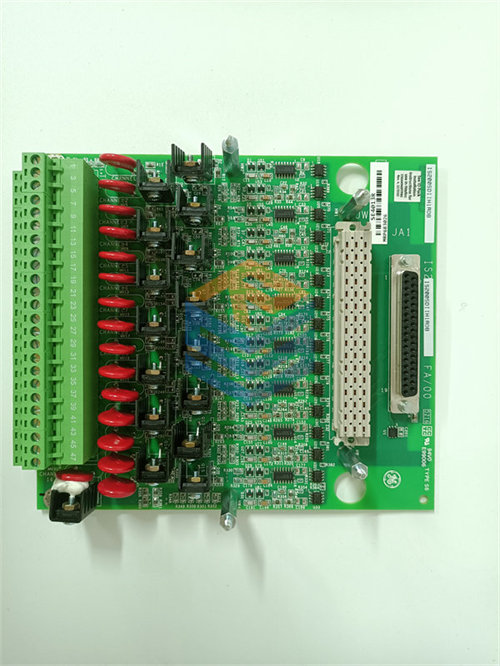

The GE IS200BPIHH1A module is a part of the GE Mark VI control system, which is widely used in industrial applications such as turbine control. This specific module serves as a Phase Logic Interface and is instrumental in managing the interface between the Distributed Control System (DCS) and the Fieldbus systems, often referred to as FOSB (Fieldbus-Optical Serial Bus).

Overview of IS200BPIHH1A

- Module Type: The IS200BPIHH1A is a Phase Logic Interface module (BPIHH1A), designed specifically to handle digital I/O and interface functions in complex control systems.

- Purpose: It facilitates communication between the control system and various field devices, bridging the connection to control signals and ensuring smooth operation of turbine and auxiliary systems.

Key Features

- Digital Input/Output Functionality:

- The module supports numerous digital inputs and outputs. This allows it to process signals from sensors and switches while outputting commands to actuators and alarms as needed.

- Fieldbus Integration:

- The IS200BPIHH1A interfaces directly with Fieldbus systems, allowing for a seamless flow of information between distributed field devices and the central control unit.

- Phase Logic Execution:

- It employs logic processing capabilities to execute critical sequences related to start-up, operation, and shutdown of turbines and associated systems, thus ensuring that all operations are coordinated effectively.

- Diagnostics and Monitoring:

- The module is equipped with diagnostics capabilities for monitoring system status and performance in real-time. This helps operators quickly identify issues and maintain system integrity.

Typical Applications

- Turbine Control: Essential for controlling the logic related to various turbine operations such as starting, stopping, and safety checks.

- Auxiliary Systems Management: Works with auxiliary systems (such as fuel supply and cooling systems) to provide comprehensive control solutions throughout the plant.

- Fieldbus Communication: Acts as a liaison between the central control system and field devices via Fieldbus, enhancing integration and operational efficiencies.

Maintenance and Troubleshooting

- Routine Inspection: Regularly check connections and wiring to ensure the reliability of signals and communication.

- Error Diagnosis: The built-in diagnostics tools can help troubleshoot issues. Review error codes and follow the recommended actions from GE’s technical documentation.

- Consult Technical Resources: For installation, configuration, and troubleshooting, always refer to the official GE documentation, as it provides in-depth guidelines and wiring diagrams specific to the IS200BPIHH1A.

Conclusion

The GE IS200BPIHH1A Phase Logic Interface module is a vital component in the GE Mark VI control system, providing crucial functions for digital communication and logic processing in turbine and plant control. Its ability to interface with Fieldbus systems expands its utility in modern industrial applications. Proper maintenance and adherence to operational guidelines are essential for ensuring optimal performance and longevity of the module. Always consult GE’s official documentation for the most accurate and detailed information.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922