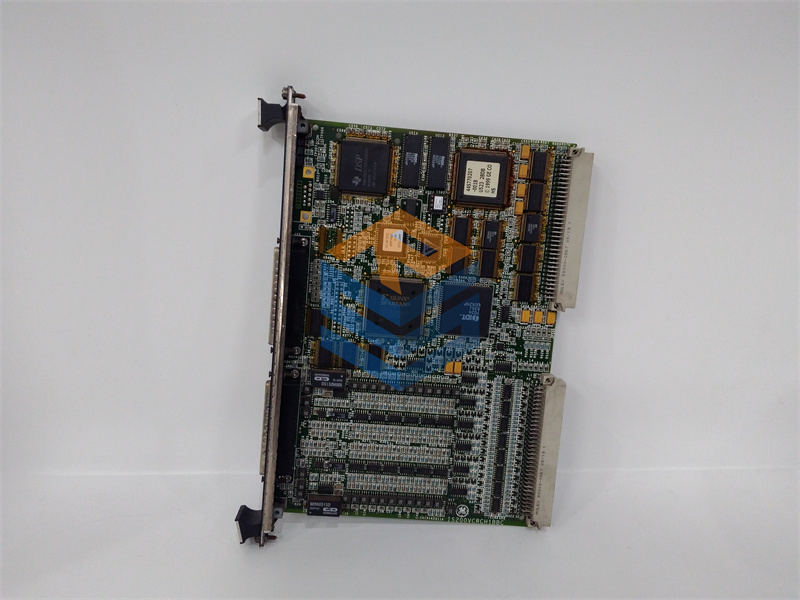

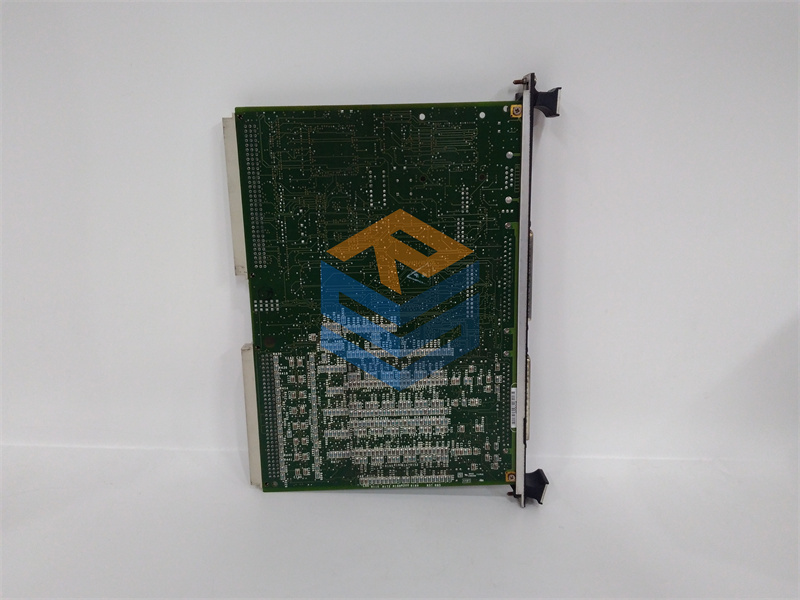

الوصف

The GE part number IS200BRTDH1A is a Distributed I/O RTD Module. It’s a component of GE’s Mark VI Speedtronic turbine control system. Its primary function is to read and process signals from RTD (Resistance Temperature Detector) sensors that are located away from the main control cabinet, providing a distributed input for temperature measurements. 🌡️

Function and Features

An RTD is a temperature sensor that changes its resistance based on temperature. The BRTD board is specifically designed to handle these signals with high accuracy and reliability.

- Distributed I/O: The “Distributed I/O” designation indicates that this board is designed for use in a remote I/O panel, which can be located closer to the sensors in the field. This reduces the amount of expensive wiring needed to run back to the main control cabinet.

- RTD Signal Processing: The board takes the low-level resistance changes from multiple RTD sensors and converts them into a clean, accurate digital temperature reading. This process includes signal conditioning, filtering, and linearization to ensure a precise measurement.

- TMR Redundancy: The Mark VI system is known for its Triple Modular Redundancy (TMR) architecture. The BRTD board is part of this system. In a TMR configuration, three identical boards process the same signal. The system then uses a voting process to determine the correct value, ensuring a high degree of reliability and fault tolerance.

- Robust Design: Like all GE industrial control components, it is built to withstand the harsh conditions of a power plant, including vibrations, temperature fluctuations, and electromagnetic interference.

Applications

The IS200BRTDH1A is used in power generation facilities that operate GE’s Mark VI turbine control systems. It is an essential component for:

- Turbine Temperature Monitoring: It provides the data necessary to monitor temperatures in critical areas of the turbine and generator, such as bearings, windings, and exhaust gas.

- Safety and Protection: The temperature readings are crucial for the turbine’s safety system, which can trigger an alarm or emergency shutdown if temperatures exceed a safe limit.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922