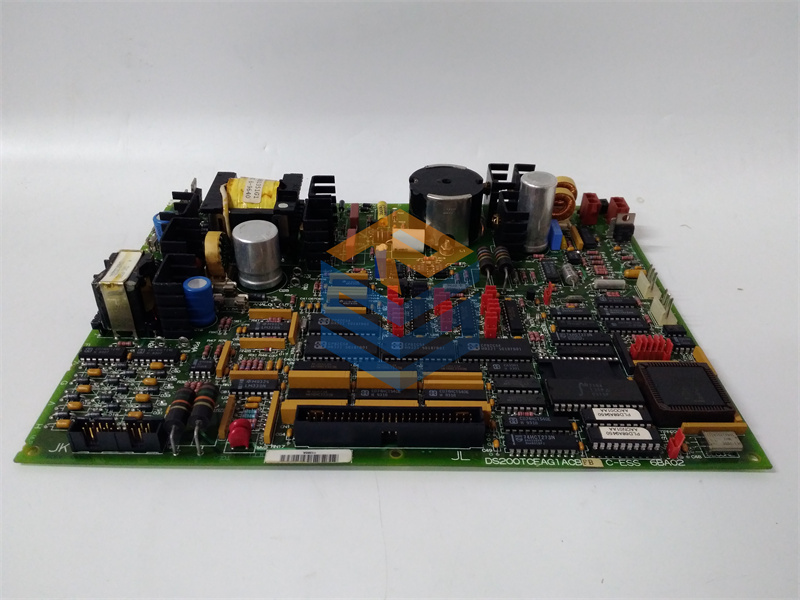

الوصف

The GE IS200DAMAG module is part of the GE Mark VI control system, commonly used in industrial applications such as gas and steam turbines. The module serves as a Digital-to-Analog Module (DAM) for managing various analog signals, and the IGBT designation refers to Insulated Gate Bipolar Transistor technology, which is often used in inverter applications for its efficiency in switching and controlling power.

Overview of GE IS200DAMAG

- Module Type: Digital-to-Analog Module (DAM)

- Function: The IS200DAMAG is primarily used to interface digital signals from the control system and convert them to analog signals. This is crucial for controlling devices such as inverters and other power electronics.

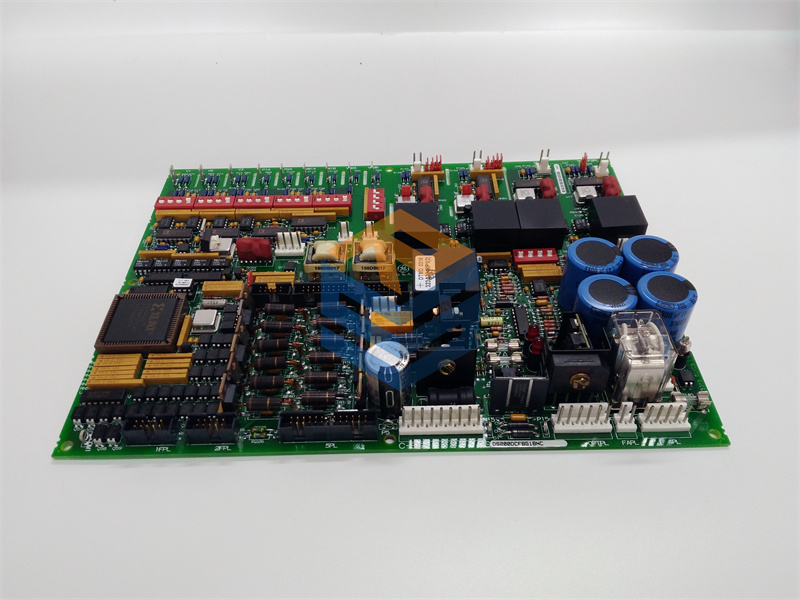

Features

- IGBT Control:

- The IS200DAMAG can be used for controlling IGBT modules in inverter applications, ensuring efficient power conversion and control in systems such as variable frequency drives (VFDs).

- Signal Conversion:

- It takes digital inputs and transforms them into analog outputs, which can be utilized to control actuators, pneumatic devices, and motors.

- Compatibility:

- The module is designed to work seamlessly with other components in the GE Mark VI control system, enhancing the overall automation and control capabilities of the system.

- Diagnostic Capabilities:

- Features built-in diagnostics for monitoring the operation and performance of IGBT devices, facilitating maintenance and troubleshooting.

- Robust Design:

- Designed to withstand industrial operational conditions, ensuring reliability and longevity in demanding environments.

Applications

- Inverter Circuits: The IS200DAMAG is typically used in applications where IGBTs are involved, allowing for efficient control of power electronics in inverters.

- Power Generation: Commonly found in gas and steam turbines where precision in power control is necessary.

- Industrial Automation: It can be utilized in numerous industrial automation systems, interfacing between control logic and physical actuators.

Maintenance and Troubleshooting

- Regular Monitoring:

- Implement routine checks on the IS200DAMAG module to ensure it functions correctly and provide accurate signal conversions.

- Utilize Diagnostic Feedback:

- Make use of diagnostic information to identify issues early and maintain optimal system performance.

- Reference Documentation:

- Consult GE’s technical documentation for the IS200DAMAG for detailed operations, installation, and troubleshooting procedures.

Conclusion

The GE IS200DAMAG is a critical component in modern industrial control systems, especially in applications that involve power conversion and control via IGBT technology. Its role in converting digital signals to analog outputs is essential for effective system integration and operational performance. For further assistance or specific technical inquiries, referring to GE’s official resources is recommended.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922