الوصف

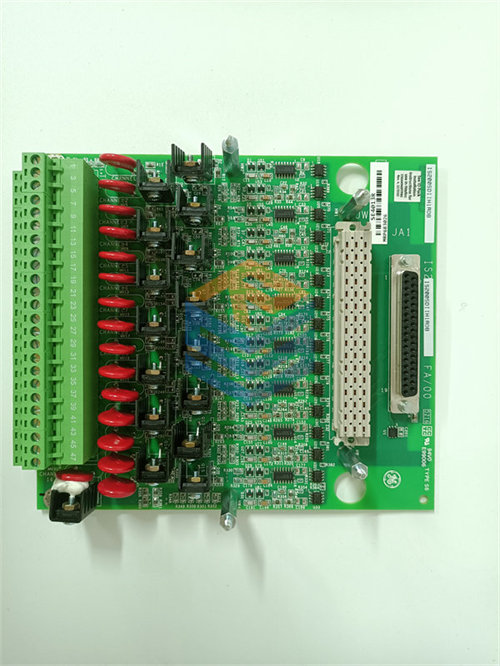

The GE IS200DAMAG is a type of IGBT (Insulated Gate Bipolar Transistor) module commonly used in the power electronics of industrial applications, such as inverters and motor drives. Specifically, it is a component found in the GE Mark VI and Mark VIe distributed control systems, which are used for control and protection in various power generation and industrial processes.

Features and Applications:

- Functionality: It is primarily used for switching applications in inverters, converting DC to AC power, which is crucial for driving AC motors.

- Performance: IGBTs provide high efficiency and fast switching capabilities, making them suitable for high-power applications.

- Temperature Management: Proper thermal management is essential for IGBT modules to ensure reliable operation and longevity.

- Integration: IS200DAMAG modules are typically part of larger control systems, interfacing with other components like sensors, control logic, and overall system architecture.

Maintenance Tips:

- Regular Inspection: Check for any signs of overheating or physical damage.

- Cooling System Check: Ensure that the cooling systems (heat sinks, fans) are functioning properly to prevent thermal failure.

- Electrical Testing: Periodically test for proper electrical performance and functionality.

If you are working with the GE IS200DAMAG IGBT or involved in maintaining a system using this component, ensure you consult the relevant technical documentation for specific handling, installation, and maintenance procedures.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922