الوصف

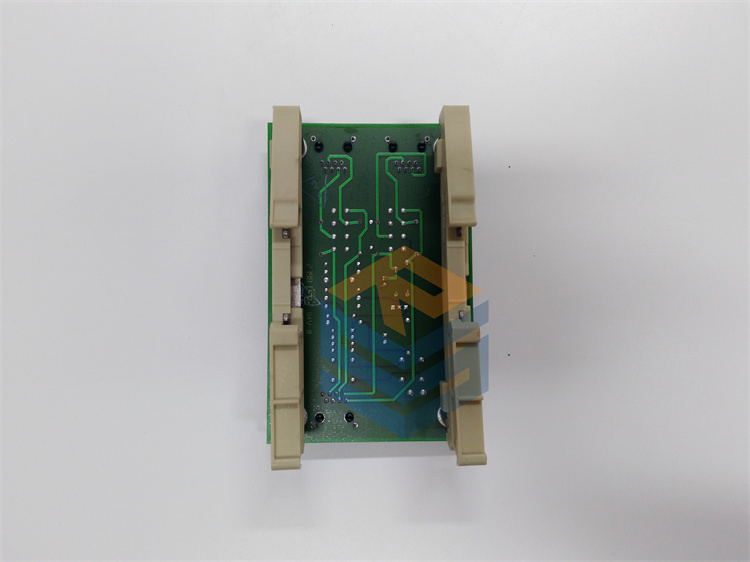

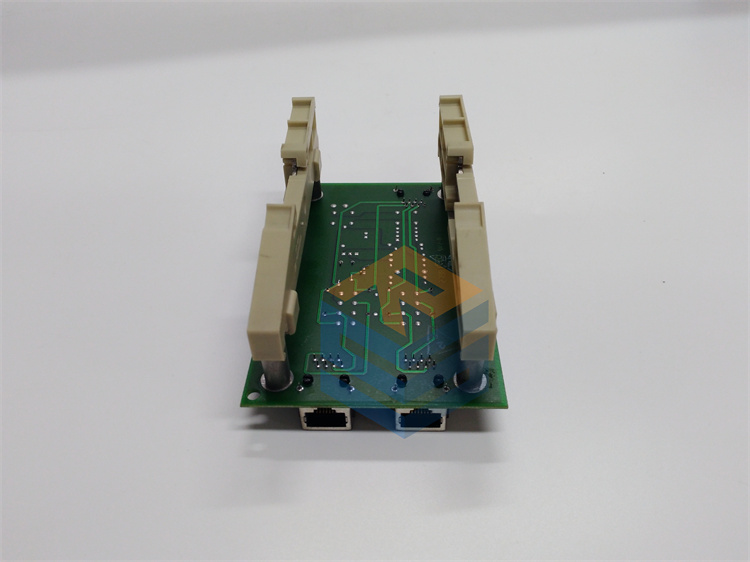

The GE IS200DAMAG1B is an IGBT (Insulated Gate Bipolar Transistor) driver module used in the GE Mark VI control system, particularly associated with applications involving inverters, such as those used in power generation systems or various industrial motor drives.

Overview of GE IS200DAMAG1B

- Module Type: IGBT Driver Module

- Functionality: The IS200DAMAG1B enables the control of IGBT devices within an inverter topology, facilitating efficient conversion between DC and AC power. This is essential in various applications, including electric drives, where precise control of motor operations is required.

Key Features

- High-Speed Switching:

- The IS200DAMAG1B supports high-speed switching capabilities essential for effective inverter operations, allowing for efficient energy conversion.

- Isolation:

- It provides electrical isolation between the control circuitry and the power devices, which is crucial for protecting sensitive components and enhancing operational safety.

- Fault Detection:

- The module includes features for fault detection, which allows the system to identify issues such as overcurrent conditions, helping to prevent damage to the inverter and associated components.

- Integration:

- Easily integrates with other components of the GE Mark VI control system, enabling streamlined communication and operation within the overall system architecture.

- Thermal Management:

- Designed with thermal considerations to manage heat dissipation effectively, thus maintaining reliability and longevity under operational conditions.

Applications

- Inverter Systems:

- Utilized in various inverter systems for driving electric motors, including those found in turbine generators and industrial applications.

- Power Generation:

- Plays a significant role in power electronics systems within power generation facilities, enabling efficient energy conversion and control.

Maintenance and Troubleshooting Recommendations

- Routine Monitoring:

- Regular monitoring of the IS200DAMAG1B module’s performance is advised to ensure it operates correctly within the set parameters.

- Diagnostic Features:

- Utilize built-in diagnostic features to determine any faults or abnormal conditions that could affect performance.

- Consult Documentation:

- For installation, operation, and troubleshooting procedures, refer to the official GE documentation tailored to the IS200DAMAG1B module.

Conclusion

The GE IS200DAMAG1B IGBT Driver Module is vital for managing and controlling IGBT devices in inverter applications, enhancing the efficiency and reliability of power conversion processes. For further technical information or queries, it is recommended to consult GE’s technical documentation or customer support resources.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922