الوصف

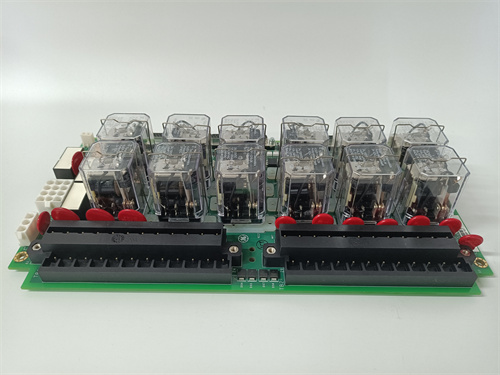

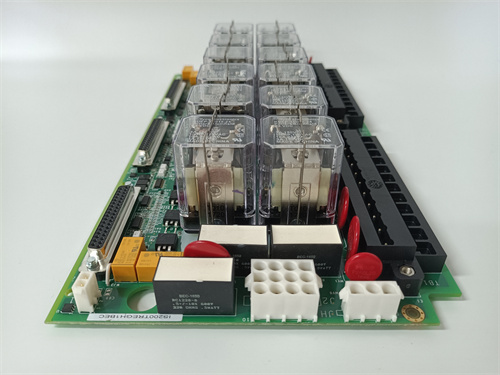

The GE IS200DSFCG1A Driver/Shunt Feedback Card (DSFC) is a specialized Printed Circuit Board (PCB) designed for use within GE’s Mark VI Speedtronic Turbine Control System and their associated Innovation Series AC Drives.1

It is a critical component that bridges the low-voltage control logic with the high-power switching components of a Variable Frequency Drive (VFD).

⚡️ Primary Function: Control & Protection for AC Drives

The IS200DSFCG1A combines two vital functions for controlling high-power AC motors, typically those used with large gas or steam turbines:2

1. IGBT Gate Driver3

- Role: The board provides the isolated driver signals required to rapidly and precisely turn the Insulated Gate Bipolar Transistors (IGBTs) in a single phase-leg of the drive’s power bridge ON and OFF.

- Mechanism: It ensures the low-voltage Pulse Width Modulation (PWM) signals from the main drive control board are converted into the high-power, isolated signals necessary to switch the IGBTs, which handle the massive current flow.

- Mounting: It is designed to mount directly onto the upper and lower IGBT modules in a phase leg, minimizing electrical interference and ensuring fast, clean switching.4

2. Shunt Feedback (Current Sensing)5

- Role: The board incorporates a shunt resistor and associated circuitry to accurately measure the current flowing through the power devices (the motor phase current).6 This is the “Shunt Feedback” component.

- Purpose: The measured current is fed back to the main control system for two main reasons:7

- Regulation: To allow the control system to precisely regulate the motor’s torque and speed.8

- Protection: To provide immediate data for fault detection (such as overcurrent) and quick shutdown of the drive to protect the expensive power components.9

🛠️ Key Specifications and System Context

| Feature | Detail |

| Functional Acronym | DSFC (Driver/Shunt Feedback Card) |

| System Compatibility | GE Mark VI Speedtronic Turbine Control System; Innovation Series PWM AC Drives (1000 Amp and 1800 Amp types). |

| Protection Features | Built-in circuitry for Overcurrent (IOC), Desaturation Faults (IGBT failure to turn ON), and Under-voltage Faults. |

| Isolation | Uses Galvanic and Optical Isolation to protect the low-voltage control circuitry from high-voltage transients and noise. |

| System Requirement | Three (3) DSFC boards are required for a 3-phase, 1000 Amp drive system (one per phase). Six (6) DSFC boards are typically required for a 1800 Amp system. |

| Diagnostics | Features multiple LED indicators to provide real-time status and quick fault identification for the driver and DC link status. |

In summary, the IS200DSFCG1A is a crucial interface and protective circuit board that enables the precision control and safe operation of high-power AC drive systems used in critical industrial applications like turbine control.10

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922