الوصف

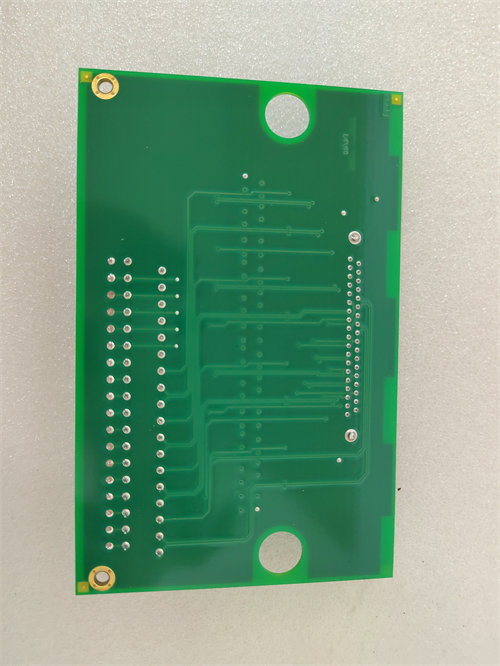

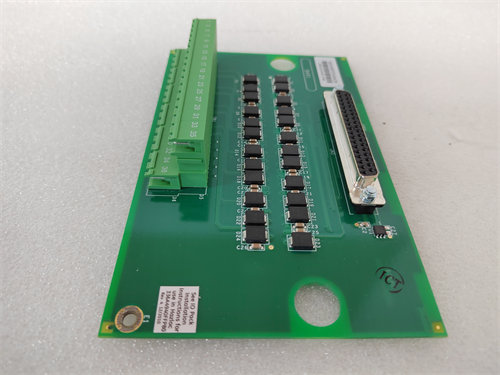

The GE IS200DSFCG1A Driver/Shunt Feedback Card (Functional Acronym: DSFC) is a critical component used in GE’s Innovation Series AC Drives and the associated Mark VI Speedtronic Turbine Control System.

Unlike the terminal boards you previously inquired about, the DSFC is not a typical I/O terminal block. Instead, it is a specialized Printed Circuit Board (PCB) with a highly specific function related to high-power semiconductor switching and current monitoring.

⚙️ Core Function: Drive Control and Protection

The primary purpose of the IS200DSFCG1A is to serve as the interface for a single phase-leg of an Insulated Gate Bipolar Transistor (IGBT) power bridge within a large AC drive system (typically 1000A or 1800A PWM bridges).

Its main responsibilities are:

- Gate Driver: It provides the necessary isolated power and signal to the gates of the upper and lower IGBTs in a phase leg. This is the “Driver” part of the name, ensuring the power semiconductors switch precisely according to the Pulse Width Modulation (PWM) signals from the main control board.

- Shunt Feedback (Current Sensing): It uses a built-in shunt resistor to accurately measure the current flowing through the power section. This is the “Shunt Feedback” part of the name. This current feedback is vital for:

- Regulation: Allowing the control system to regulate and maintain the correct motor torque and speed.

- Protection: Providing immediate feedback to the control system for fault detection.

🛡️ Key Features and Protection

The DSFC board incorporates several features essential for operating high-voltage, high-current power electronics:

- Isolation: It uses galvanic and optical isolation to protect the low-voltage control circuitry from the high-voltage power section of the drive.

- Fault Detection: It includes circuits to detect critical conditions and quickly shut down the IGBTs to prevent damage, such as:

- Desaturation Faults: Occurs when the IGBT fails to turn fully ON (a state known as desaturation).

- Overcurrent (IOC) Faults: Occurs when the current exceeds the rated limit.

- Under-voltage Faults: Indicates a loss of power to the driver circuitry.

- Mounting: It mounts directly onto the upper and lower IGBT modules in a phase leg, keeping connections extremely short to minimize electrical noise and stray inductance, which is critical for fast-switching power electronics.

- System Scale: In a complete 3-phase system, three DSFC boards are required for a 1000A drive, and six boards (two per phase) are typically required for an 1800A drive.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922