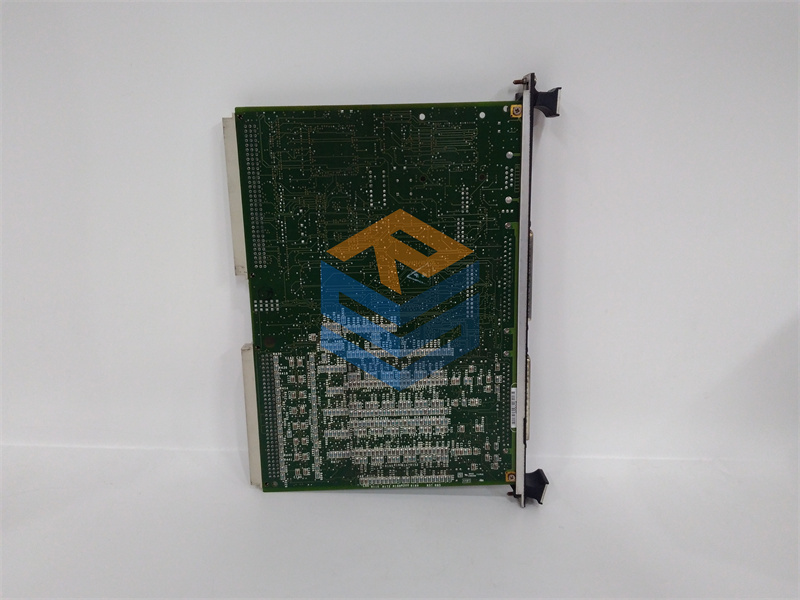

الوصف

The GE part number IS200DSVOH1A is a Servo Terminal Board. It is a component of GE’s Mark VI Speedtronic turbine control system. Its primary function is to serve as a wiring interface for a servo valve, providing a clean and organized connection point to a main processor board. ⚙️

Function and Key Features

A servo valve is an electro-hydraulic device that precisely controls the flow of a fluid (such as hydraulic oil) to a large actuator, which in turn moves a mechanical component like a steam or fuel valve. The DSVO board manages the electrical signals for this valve.

- Servo Valve Interface: The board provides screw terminals or other connection points for the wiring that goes to the servo valve. This wiring includes the command signal from the control system and feedback signals from a Linear Variable Differential Transformer (LVDT) that measures the valve’s position.

- Signal Conditioning: The board is designed to handle the delicate analog signals required for servo control. It may include filtering and shielding to protect the signals from electrical noise in the industrial environment, which is critical for precise and stable control.

- Removable: This board is likely designed to be easily removable, which simplifies installation and maintenance. A technician can unplug the board from the main control card without having to disconnect all the field wiring, reducing downtime.

- Robust Design: Like all GE industrial control components, it is built to withstand the harsh conditions of a power plant, including vibrations and temperature fluctuations.

Applications

The IS200DSVOH1A is used in power generation facilities that operate GE’s Mark VI turbine control systems. It is an essential component for:

- Hydraulic Control: It provides the critical interface for controlling hydraulically operated valves, such as those that regulate the flow of fuel or steam to the turbine.

- Precision Control: By ensuring the integrity of the servo valve signals, it contributes to the precise and stable control of the turbine’s speed and load.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922