الوصف

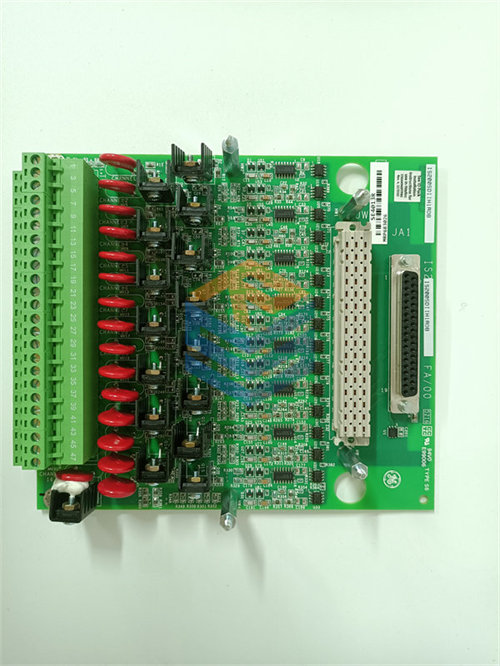

The GE IS200IVFBG1A is a specific version of the Integrated Voltage Feedback Board (IVFB) used in the Mark VI control system, which is integral in managing gas and steam turbines. This module is designed to provide current feedback for PWM (Pulse Width Modulation) signals, playing a critical role in the precise control of actuators and other components reliant on PWM control strategies.

Overview of IS200IVFBG1A (PWM Current Feedback Module)

Functionality:

- The IS200IVFBG1A module monitors and relays current feedback from PWM outputs, enabling the control system to make real-time adjustments based on the operational state of the machinery.

- This feedback loop is essential for maintaining the desired performance levels of actuators, enhancing system stability and reliability.

Key Features

- Accurate Current Monitoring: The module captures and provides feedback on current levels, which is crucial for dynamic control applications.

- Compatibility with Mark VI: Ensures seamless integration into the existing Mark VI architecture, facilitating easy installation and configuration.

- Robust Design: Built to withstand the demanding environments of turbine operations while providing accurate and reliable data.

Typical Applications

- Turbine Control Systems: Mainly used in gas and steam turbine applications where precise current feedback is necessary for smooth operation.

- Actuator Control: Effective in scenarios where controlling the position or speed of actuators based on real-time current feedback is required.

Installation and Configuration

- Safety Procedures: Always ensure safety measures are adhered to. Disconnect power from the control system before beginning installation to avoid electric shock.

- Module Installation: Insert the IS200IVFBG1A into the designated slot in the Mark VI control rack, ensuring proper alignment and secure connection.

- Wiring Connections: Connect the module according to the wiring diagrams found in the installation manual provided by GE, making sure all connections are tight and correctly oriented.

- System Configuration: Use the appropriate Mark VI software for configuring the parameters relevant to the IS200IVFBG1A module to align with system requirements.

- Testing: After installation and configuration, conduct thorough testing to ensure the module is communicating correctly and accurately relaying current feedback.

Troubleshooting

If you encounter issues:

- Connection Verification: Check that all wiring connections are secure and properly secured as per the installation guidelines.

- Configuration Verification: Ensure that the module settings are correctly configured in the control system software, matching the operational requirements.

- Monitor for Errors: If alarms or errors occur, consult the control system diagnostics to identify any issues related to feedback accuracy or communication failures.

Documentation

Refer to the official GE documentation specific to the IS200IVFBG1A for comprehensive installation instructions, operational guidance, and troubleshooting steps tailored to your specific application and system configuration.

Conclusion

The GE IS200IVFBG1A plays a vital role in ensuring effective current feedback within the Mark VI control system, enhancing precision in turbine operation. Correct installation, configuration, and ongoing maintenance are essential for optimal performance in applications requiring PWM control.

For complex configurations or support, consult GE technical support or experienced personnel familiar with Mark VI systems to ensure proper implementation and operation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922