الوصف

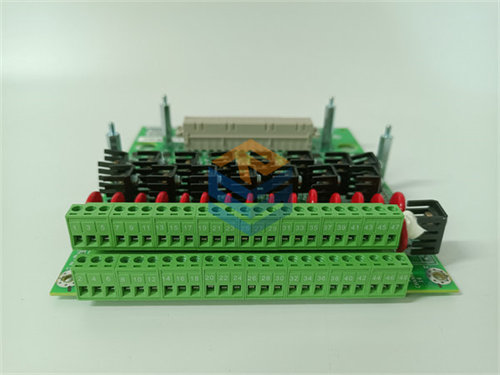

The GE IS200JGNDG1AAA is a Shield Ground Board (JGND) designed for use in General Electric’s high-reliability control systems, specifically the Mark VI Speedtronic Turbine Control System and the Mark VIe Distributed Control System.

Its function is fundamental to the system’s electrical integrity, providing a secure point for terminating cable shields to mitigate electrical noise.

⚙️ Core Function: Shield Grounding

The primary role of the IS200JGNDG1AAA is to manage the grounding of cable shields to ensure a clean signal environment:

-

EMI Mitigation: The board provides a dedicated, low-impedance path for connecting the shield drain wires of external field cables. This is crucial for shunting Electromagnetic Interference (EMI) and radio-frequency noise away from the sensitive signal conductors.

-

Signal Integrity: By effectively grounding the shields, the board helps prevent noise from corrupting the low-level signals (e.g., analog inputs from sensors, thermocouples, or RTDs) that are vital for the accurate operation of the turbine or generator.

-

Ground Separation: The board allows shield grounds to be terminated separately from the signal grounds on the primary I/O board. This separation is often required by best practice to prevent shield currents from flowing into the signal ground path and introducing noise.

🔌 Technical and Installation Details

-

Product Type: Shield Ground Terminal Board.

-

Terminals: The board is equipped with multiple screw terminals (typically 24 positions) in a block configuration (often Euro-type terminal blocks) for connecting the bare shield drain wires.

-

Mounting: The board is small and mounts directly to a sheet metal bracket within the control cabinet, adjacent to the main terminal board.

-

Grounding Mechanism: The board establishes its ground connection through the mounting hardware to the sheet metal bracket. Best practice dictates a direct conductive path (i.e., no nylon washers) between the board and the grounded sheet metal for the most effective EMI drainage.

-

Revision: The G1AAA suffix indicates the initial hardware group and artwork revision, with multiple subsequent assembly/manufacturing revisions. The core shield grounding function remains constant.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922