الوصف

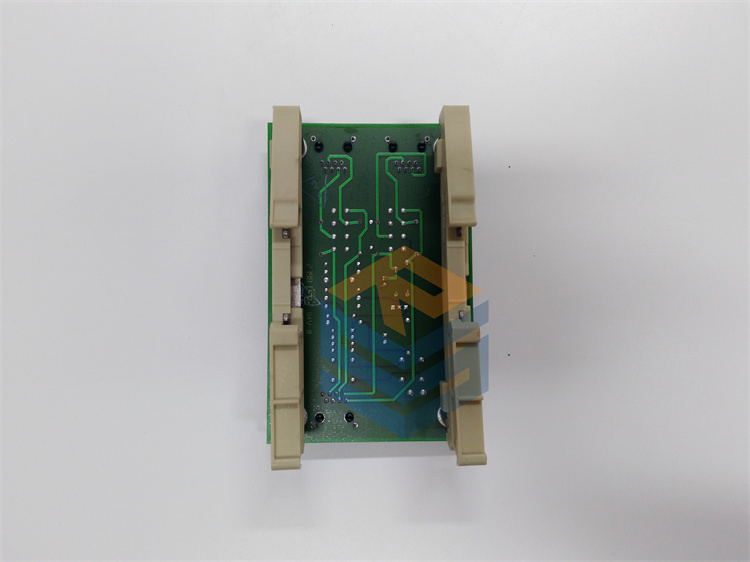

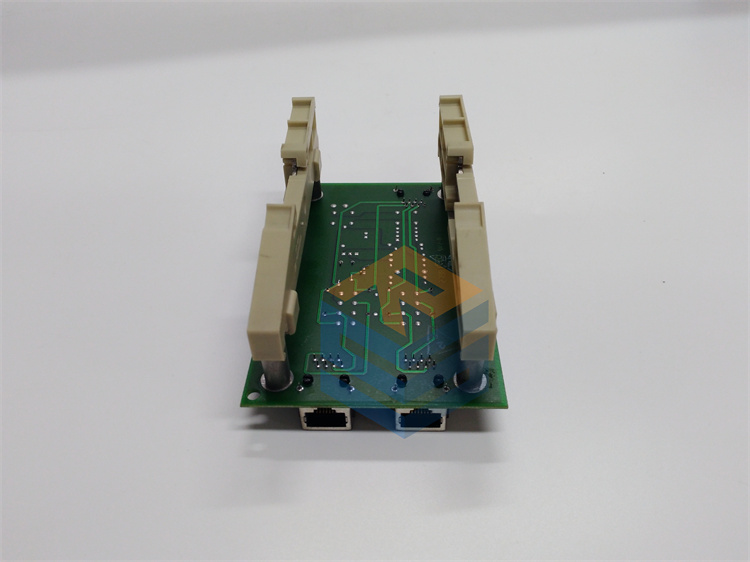

The GE IS200JPDDG1ADCPDM is a specific type of Joint Pulse Displacement Board (JPDB) used in the Mark VI control system, developed by General Electric, which is widely utilized in gas and steam turbine applications. This module is designed for positioning control and feedback signal processing, playing a crucial role in ensuring precise and reliable operation of the turbine system.

Overview of IS200JPDDG1ADCPDM (Joint Pulse Displacement Board)

Functionality:

- The IS200JPDDG1ADCPDM is responsible for processing displacement feedback signals from various sensors. These signals are essential for accurate control of actuators in turbine applications.

- By providing real-time feedback regarding the position of mechanical components, the board aids in the optimal functioning and safety of turbine operations.

Key Features

- Accurate Signal Processing: Processes input signals from position sensors to ensure accurate displacement measurements.

- Seamless Integration: Designed to integrate smoothly with the Mark VI control architecture, making it a compatible option for existing systems.

- Durability: Engineered to operate under the challenging conditions typical in turbine environments, ensuring reliable performance over time.

Typical Applications

- Turbine Control: Used in gas and steam turbines for controlling actuator positions and ensuring proper alignment of turbine mechanisms.

- Industrial Automation: Suitable for applications in industrial settings where precise mechanical control and monitoring are required.

Installation and Configuration

- Safety First: Before installation, ensure that all power sources to the control system are disconnected to avoid any electrical hazards.

- Installing the Module: Insert the IS200JPDDG1ADCPDM into the appropriate slot in the Mark VI control rack, making sure it is fully seated and secure.

- Connecting Wiring: Follow the provided wiring diagrams to connect the necessary sensors and outputs to the module correctly.

- Configuration: Use the configuration tools associated with the Mark VI system to set up the module, defining necessary parameters for its operation.

- Conduct Testing: After installation, test the module to verify that it is operational and effectively relaying feedback to the control system.

Troubleshooting

Common troubleshooting steps for the IS200JPDDG1ADCPDM include:

- Connection Verification: Check that all wiring connections are secure and properly configured according to the installation manual.

- Physical Inspection: Inspect the board for any physical damage, corrosion, or signs of wear that could affect function.

- Diagnostics: Use the diagnostic features of the Mark VI system to identify any error codes or issues with input or output signals.

Documentation

It is important to consult the official documentation specific to the IS200JPDDG1ADCPDM for detailed instructions on installation, operation, and troubleshooting tailored to this board. This information can often be found in the technical manuals provided by GE.

Conclusion

The GE IS200JPDDG1ADCPDM Joint Pulse Displacement Board plays a vital role in the effectiveness and reliability of the Mark VI control system in turbine applications. Proper installation, configuration, and maintenance are essential for ensuring optimal performance. For more complex issues or technical assistance, reaching out to GE’s technical support or consulting with experts familiar with the Mark VI system is recommended.

If you need further information or specific details regarding configurations, applications, or other aspects related to this module, please feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922