الوصف

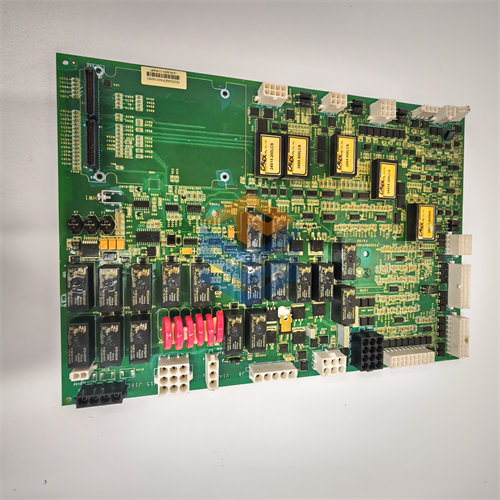

The GE IS200TBAIH1C is another variant of the terminal board designed for the GE Mark VI control system. Like its predecessors, the IS200TBAIH1C serves as an analog input terminal board and is intended for use in industrial automation applications, particularly in sectors like power generation and process control.

Key Features:

- Analog Input Channels: This board typically accommodates multiple analog input channels, which can connect to various field devices (like sensors) to monitor parameters such as temperature, pressure, and flow.

- Signal Conditioning: It incorporates hardware for signal conditioning, ensuring that the incoming analog signals are processed accurately for the control system.

- Connector Terminals: The board features terminal blocks that facilitate easy connections and wiring for field instrumentation.

- Compatibility: Designed to work seamlessly within the Mark VI control system architecture, the board supports integration with other control components for comprehensive process management.

Applications:

- Utilized in various industrial environments for real-time data acquisition and monitoring.

- Commonly found in power plants, manufacturing facilities, and other process industries requiring robust and reliable analog input capabilities.

Maintenance and Troubleshooting:

- Visual Inspections: Regular inspections of wiring and connectors can help identify potential issues like corrosion or damage.

- Calibration: Routine calibration may be required to maintain accurate readings from connected sensors.

- Diagnostics: Utilize diagnostic tools and system software to monitor board performance and troubleshoot any anomalies.

- Documentation: Always refer to the official GE documentation for wiring diagrams, installation guidelines, and troubleshooting steps specific to the IS200TBAIH1C.

Conclusion:

The GE IS200TBAIH1C terminal board is essential for integrating and managing analog inputs within the Mark VI control system. Its role in facilitating accurate data communication from field devices makes it vital for efficient industrial operations. For detailed information regarding specifications, installation, and operation, consulting the manufacturer’s documentation is recommended.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922