الوصف

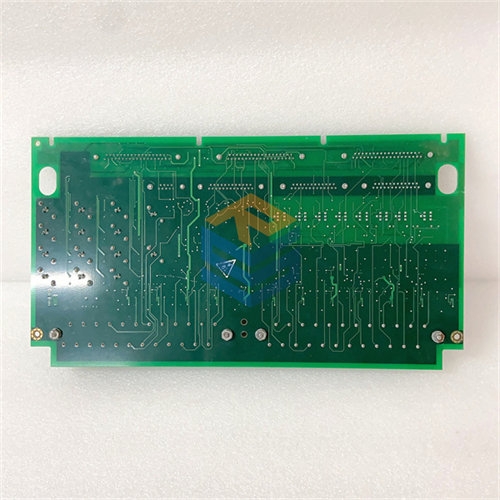

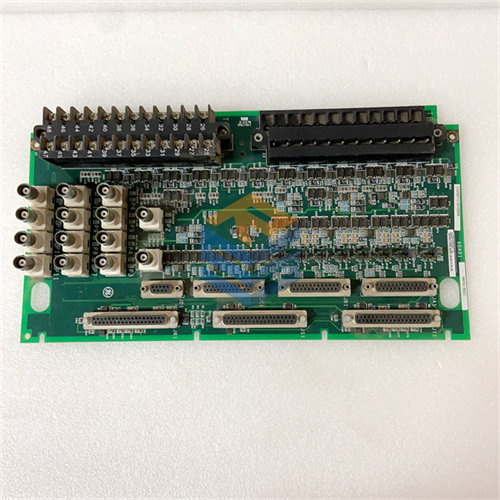

The GE IS200TBAIH1CDC is another model of the termination board utilized in the GE Mark VI control system. Specifically designed for handling analog input signals, this board is essential in various industrial automation settings, including power generation and process control applications.

Key Features:

- Analog Input Channels: The IS200TBAIH1CDC typically offers multiple channels for connecting to analog sensors and devices, enabling the measurement of critical parameters such as temperature, flow, and pressure.

- Signal Conditioning: The board is equipped with circuitry designed to condition the incoming analog signals, ensuring they are accurate and suitable for processing by the control system.

- Wiring Terminals: It features terminal blocks for straightforward connections to field devices, facilitating ease of installation and maintenance.

- Integration Capabilities: This board integrates smoothly within the GE Mark VI architecture, supporting the overall functionality and communication of the control system.

Applications:

- Commonly found in power generation facilities, oil refining, chemical processing, and various manufacturing environments where real-time monitoring and control are crucial.

- Plays a vital role in gathering process data, enhancing operational efficiency, and facilitating decision-making based on real-time information.

Maintenance and Troubleshooting:

- Inspection: Regularly inspect the board for potential signs of wear, damage, or corrosion on the terminal connections and components.

- Calibration: Perform routine calibration of sensors to maintain measurement accuracy and reliability.

- Diagnostics: Utilize diagnostic tools and software to monitor performance and troubleshoot any issues related to the analog inputs.

- Documentation: For detailed installation, wiring diagrams, and troubleshooting, referring to the official GE documentation specific to the IS200TBAIH1CDC is crucial.

Conclusion:

The GE IS200TBAIH1CDC termination board is integral to the Mark VI control system, allowing for effective integration of analog inputs from various sensors. Its reliable performance is essential for maintaining operational excellence in industrial applications. For specific technical details and operational guidance, it is advisable to consult the manufacturer’s documentation.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922