الوصف

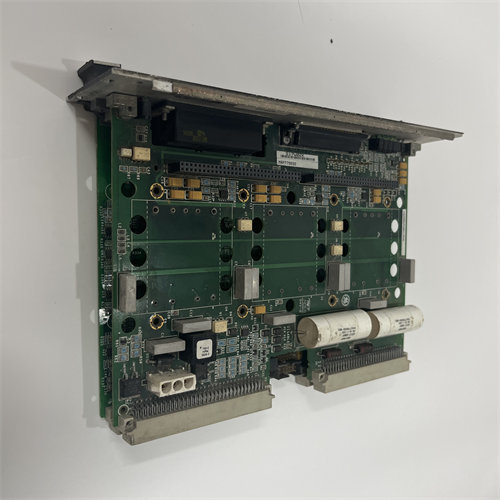

The GE IS200TRLYH2C is a relay termination board used in the General Electric Mark VI (MK6) control system, which is widely used in turbine and industrial applications. This board plays a crucial role in managing relay output functions essential for control, safety, and automation strategies. Here is an overview of the board and its features:

Overview of GE IS200TRLYH2C

- Model: GE IS200TRLYH2C

- Type: Relay Termination Board

- Application: Functions within the Mark VI control system to provide output signals for various operational controls and safety mechanisms.

Key Features

- Relay Outputs: The IS200TRLYH2C offers multiple relay outputs that can manage different operational commands, such as shutting down equipment, triggering alarms, or activating other control signals.

- Signal Conditioning: It conditions and processes incoming signals to ensure accurate relay activation based on the control system’s logic.

- Durability: Designed to endure harsh industrial environments, ensuring reliability and longevity in demanding applications.

Functional Description

- Integration with Control System: The board is integrated with the Mark VI system, allowing seamless communication with other control modules and input devices.

- Safety and Control Functions: It supports critical safety functions, responding appropriately to inputs from sensors and control algorithms.

Maintenance and Operational Guidelines

- Routine Inspections: Regularly examine the board for any physical damage, heat buildup, or loose connections.

- Check Connections: Ensure that all wiring is secure and free from corrosion or wear.

- Cleaning: Keep the board and surrounding area clean to prevent contamination that could impact performance.

Troubleshooting Relay Output Issues

If you are experiencing issues with relay outputs on the IS200TRLYH2C board, consider the following steps:

- Verify Power Supply: Ensure that the board is receiving the correct power input and that all associated fuses or breakers are functioning properly.

- Examine Relay Functionality: Check the individual relay states. If any relay appears damaged or is not functioning, it may need to be replaced.

- Inspect Input Signals: Make sure that the control system is sending the correct signals to the board. Verify the logic and any relevant configuration settings.

- Look for Fault Codes: If available, check the control system for any fault codes that could provide insight into the malfunction.

- Isolate and Test: If possible, isolate the board from the control system to test relay functions independently to rule out external issues.

- Documentation Reference: Consult the maintenance manuals specific to the IS200TRLYH2C for detailed troubleshooting steps, wiring diagrams, and specifications.

Technical Support

For comprehensive troubleshooting assistance, detailed technical data, and support, you can refer to GE’s official documentation or contact their technical support team. This will help ensure the optimal operation and reliability of the IS200TRLYH2C termination board in your application.

If you have any additional questions or need further assistance, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922