الوصف

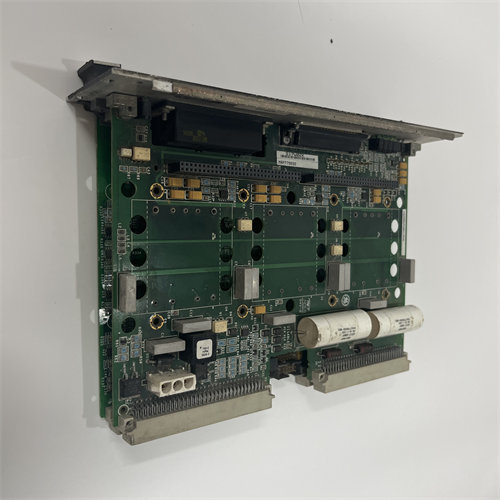

The GE IS200TRPGH is a trip relay termination board used in General Electric’s Mark VI (MK6) control system, which is integral to turbine and industrial control applications. This board plays a crucial role in the management of trip functions and other safety features within the control architecture.

Overview of GE IS200TRPGH

- Model: IS200TRPGH

- Type: Trip Relay Termination Board

- Primary Function: The IS200TRPGH is designed to facilitate safety-related functions, specifically to manage and interface trip relay outputs that are essential for protecting the system from unsafe operating conditions.

Key Features

- Trip Relay Outputs: This termination board typically includes multiple trip relay outputs that can respond to various signals from the control system to initiate trips or alarms. This is critical for ensuring safe operation of turbines and associated equipment.

- Electrical Isolation: The design includes measures to provide electrical isolation between the control signals and relay outputs, which helps protect sensitive electronics from possible surges or faults.

- Indication LEDs: The IS200TRPGH may feature LEDs that provide visual feedback on the status of each relay, making it easier to monitor operations and identify issues during maintenance or troubleshooting.

- Robust Construction: Engineered for durability, the IS200TRPGH is built to operate reliably in harsh industrial environments.

Applications

The IS200TRPGH board is commonly used in:

- Turbine Control Systems: For managing trip functions that protect against over-speed, low pressure, or other unsafe conditions.

- Safety Systems: Triggers alarms and action sequences in the case of detection of hazardous conditions.

- Industrial Automation: Interfaces with safety equipment in various industrial applications to maintain operational integrity.

Troubleshooting and Maintenance

If you encounter issues with the IS200TRPGH termination board, consider the following troubleshooting steps:

- Visual Inspection:

- Inspect the board for any visible signs of damage, overheating, or component failure.

- Ensure all connectors and wiring are secure and free of corrosion.

- Power Supply Check:

- Confirm that the board is receiving the proper power supply voltage.

- Look for any blown fuses or tripped circuit breakers that might disrupt power to the board.

- Test Relay Operation:

- Verify the operation of each trip relay. You can perform functional tests to ensure they operate correctly when triggered by the control system.

- Use the status LEDs (if available) to monitor relay activity and determine whether they are responding as intended.

- Inspect Input Signals:

- Check that signals from the control system are reaching the board correctly. This may involve using diagnostic software or tools.

- Refer to Documentation:

- Consult technical manuals for the IS200TRPGH and overall MK6 system to access specific troubleshooting and repair procedures.

- Isolation Testing:

- If feasible, isolate the board and test it independently of the control system to determine if failures persist.

- Consider Replacement:

- If, after thorough troubleshooting, the board still fails to operate correctly, consider replacing it with a functionally verified unit to see if that resolves the issue.

Technical Support

For more detailed guidance, specific troubleshooting procedures, or to obtain technical documentation regarding the IS200TRPGH board, you can contact GE’s technical support. They will provide valuable insights that conform to industry standards and practices for maintaining the MK6 control system effectively.

If you have any further questions or need additional information, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922