الوصف

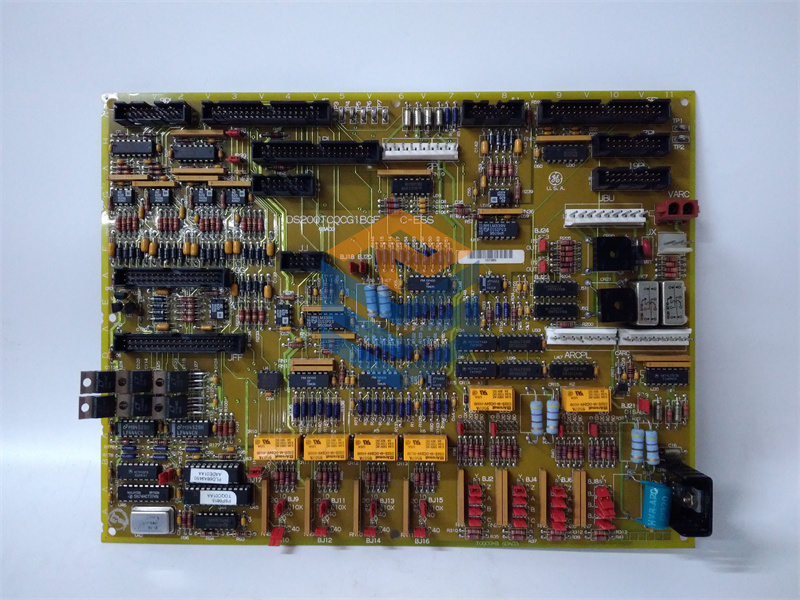

The GE IS200TRPSH is a termination board utilized in General Electric’s Mark VI (MK6) control system, primarily designed for various industrial applications, including turbine control systems. The board serves critical functions related to the termination of trip signals and is integral to safety and operational reliability in these systems.

Overview of GE IS200TRPSH

- Model: IS200TRPSH

- Type: Termination Board

- Primary Function: The IS200TRPSH board provides a termination point for wiring to relay outputs, ensuring that signals can be routed correctly to safety devices and trip relays within the control system.

Key Features

- Trip Relay Management:

- The IS200TRPSH board can manage multiple trip relay connections, ensuring that critical safety responses can be executed when necessary.

- Electrical Isolation:

- It provides electrical isolation between the control system and the output devices to protect against potential faults that may arise in the machinery.

- Signal Integrity:

- The design of the board preserves the integrity of the signal being transferred from the control system to the output devices, helping to ensure reliable performance in response operations.

- User-Friendly Interface:

- The board includes clearly labeled terminals for ease of connection, making it accessible for installation and maintenance.

- Durable Construction:

- The IS200TRPSH is constructed to withstand the environmental demands typically found in industrial settings, promoting long-term reliability.

Applications

The IS200TRPSH board is commonly employed in:

- Turbine Control Systems: As part of the safety architecture, managing relay outputs for emergency shutdowns and alarms.

- Industrial Automation: Providing reliable termination for various control signals that engage safety mechanisms.

- System Monitoring: Assisting in the monitoring of operational parameters by facilitating effective communication between the control system and output devices.

Troubleshooting and Maintenance

If issues arise with the IS200TRPSH board, consider the following steps for troubleshooting:

- Visual Inspection:

- Inspect the board for any signs of damage or component failure, such as burnt markings or disconnected wires.

- Power Supply Check:

- Verify that the board is receiving the correct voltage and that all power connections are secure.

- Connection Testing:

- Ensure that all wire connections are properly terminated and that there are no loose connections that could affect operation.

- Signal Testing:

- If applicable, use diagnostic tools to check for proper signal integrity and communication with connected devices.

- Consult Technical Documentation:

- Refer to the relevant manuals and technical documentation for wiring diagrams and operational guidelines specific to the IS200TRPSH board.

- Perform Isolation Testing:

- If possible, test the board in isolation from the larger control system to determine if the problem lies with the board or in external components.

- Consider Replacement:

- If problems persist after thorough testing and troubleshooting, it may be necessary to replace the board to restore proper functioning.

Technical Support

For further information, detailed specifications, or technical support related to the IS200TRPSH termination board, you can contact GE’s technical support team or refer to the specific manuals and resources available for the Mark VI control system. They can provide expert assistance tailored to your operational needs.

If you have any more questions or need additional assistance, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922