الوصف

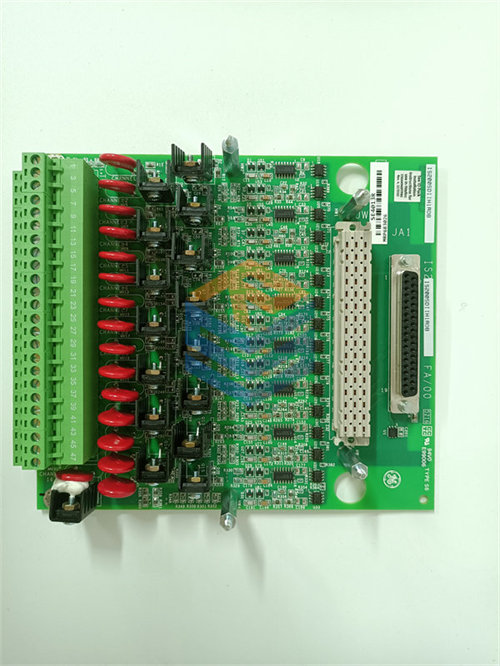

The GE IS200TRTDH is an RTD (Resistance Temperature Detector) terminal board used in General Electric’s Mark VI (MK6) control system, which is widely applied in various industrial settings, primarily in turbine control systems.

Overview of GE IS200TRTDH

- Model: IS200TRTDH

- Type: RTD Terminal Board

- Function: The IS200TRTDH serves as the interface for connecting RTD sensors to the Mark VI control system, allowing for temperature measurements critical for system monitoring and control.

Key Features

- Temperature Sensing:

- The board is designed to interface with RTD sensors, which provide accurate temperature readings necessary for monitoring the operating conditions of turbines and other equipment.

- Multi-Channel Capability:

- Typically, the IS200TRTDH can accommodate multiple RTD inputs, allowing for the monitoring of various temperature points within the system.

- Signal Conditioning:

- The board may include circuitry to condition the signals from the RTD sensors, ensuring that the readings are accurate and reliable before they are sent to the control system.

- Ease of Integration:

- Designed for straightforward installation, the board features clearly labeled terminals that simplify the process of connecting RTDs and ensures correct wiring.

- Durable and Reliable:

- Built to withstand harsh conditions often found in industrial environments, the board’s construction is made to be durable, ensuring long-term performance.

- Electrical Isolation:

- Provides electrical isolation between the RTD sensors and the control system, protecting sensitive electronics from potential faults.

Applications

The IS200TRTDH terminal board is commonly used in:

- Turbine Control Systems: It enables precise temperature monitoring, which is crucial for safe and efficient turbine operation.

- Industrial Automation: Interfacing with RTD sensors across various processes to maintain operational temperatures within specified limits.

- Monitoring and Safety Systems: Assisting in the detection of potential overheating or other conditions that could affect equipment performance.

Troubleshooting and Maintenance

To ensure the proper functioning of the IS200TRTDH board, consider the following troubleshooting tips:

- Visual Inspection:

- Inspect the board for any damage, corrosion, or signs of wear, such as burnt traces or loose connections.

- Power Supply Verification:

- Check that the board is receiving the correct power levels and that all connections are secure.

- Connection Verification:

- Ensure all RTD sensors are properly connected and terminals are tight.

- Signal Integrity Testing:

- Use diagnostic equipment to verify that the RTD signals are being properly detected and transmitted to the control system.

- Consult Technical Documentation:

- Refer to the relevant manuals and specifications for the IS200TRTDH for wiring diagrams and operational guidelines.

- Isolate Testing:

- If issues arise, consider testing the board in isolation to determine if the problem is within the board itself or with external components.

- Replace if Necessary:

- If troubleshooting does not resolve the problem, consider replacing the board to restore normal operation.

Technical Support

For more detailed specifications or technical support regarding the GE IS200TRTDH RTD terminal board, you can contact GE’s technical support or refer to the appropriate documentation related to the Mark VI control system. Their resources can provide tailored support to address your operational needs.

If you have additional questions or need further details, please feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922