الوصف

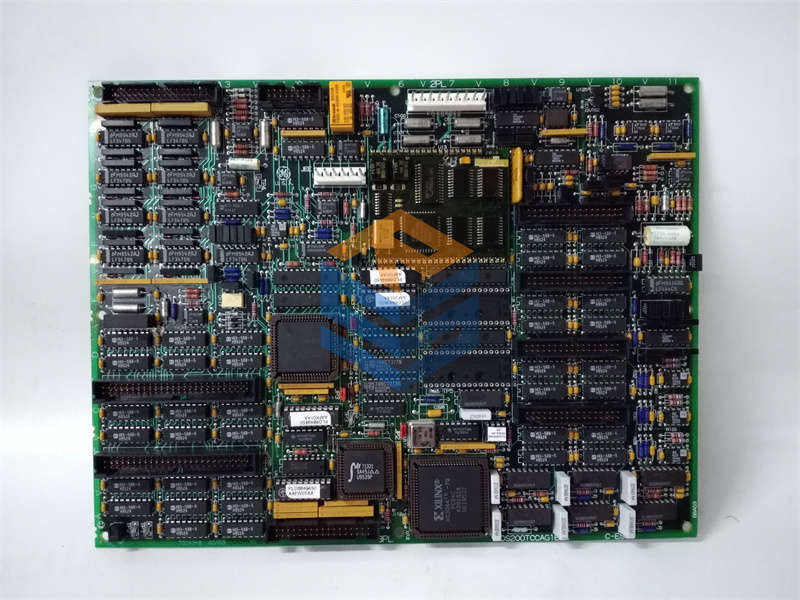

The GE IS200TRTDH1BCC is another variant of the RTD (Resistance Temperature Detector) terminal board designed for use within General Electric’s Mark VI (MK6) control system. This particular board is essential for interfacing with RTD sensors, allowing precise temperature monitoring in various industrial applications, particularly in power generation systems.

Overview of GE IS200TRTDH1BCC

- Model: IS200TRTDH1BCC

- Type: RTD Terminal Board

- Control System: Mark VI (MK6) used in gas and steam turbine control applications.

- Function: The board connects multiple RTD sensors to the control system, enabling accurate temperature measurement and monitoring essential for system performance and safety.

Key Features

- Multiple RTD Inputs:

- The IS200TRTDH1BCC typically accommodates multiple channels for connecting RTD temperature sensors, which is vital for monitoring various parts of a system.

- High Precision:

- It allows for accurate temperature readings, which are critical for the safe and efficient operation of machinery in demanding environments.

- Signal Conditioning:

- Integrated signal conditioning ensures that the data from the RTD sensors is clean and free from interference, allowing for higher fidelity temperature monitoring.

- Robustness:

- Designed to operate reliably in harsh industrial conditions, ensuring longevity and consistent performance.

- Clear Terminal Labeling:

- The layout of the board features clear labels for easy identification and connection of RTD sensors, simplifying installation and maintenance.

- Electrical Isolation:

- Isolates the RTD inputs from other parts of the control system, protecting sensitive components from voltage spikes or grounding issues.

Applications

The IS200TRTDH1BCC board is widely used in applications such as:

- Turbine Control Systems: Monitoring the temperature of critical components within turbines to facilitate safe operation.

- Industrial Process Monitoring: Used in various process control scenarios requiring temperature feedback for automated systems.

- Safety Monitoring Systems: Providing essential data to monitoring systems that ensure the operational safety of industrial equipment.

Troubleshooting and Maintenance

To maintain the functionality and reliability of the IS200TRTDH1BCC terminal board, follow these best practices:

- Routine Inspections:

- Regularly inspect the board for physical damage, loose connections, or corrosion.

- Power Supply Verification:

- Confirm that the board is receiving appropriate voltage and that all connections are secure.

- Connection Checks:

- Verify that all RTD sensors are correctly connected to their respective terminals and are functioning as intended.

- Signal Integrity Testing:

- Use diagnostic equipment to check the quality of signals coming from the RTD sensors to ensure they are within expected ranges.

- Reference Technical Documentation:

- Consult with the relevant technical manuals for wiring diagrams and operational instructions specific to the IS200TRTDH1BCC.

- Isolate Components:

- In case of malfunction, isolate the board to determine if the issue is with the board itself or related to external systems.

- Replacement:

- If troubleshooting fails to resolve any issues, consider replacing the board to ensure uninterrupted operation.

Technical Support

For further assistance regarding the GE IS200TRTDH1BCC RTD terminal board, including detailed specifications or troubleshooting guides, reach out to GE’s technical support or refer to the official documentation associated with the Mark VI control system.

If you have any more questions or require additional information, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922