الوصف

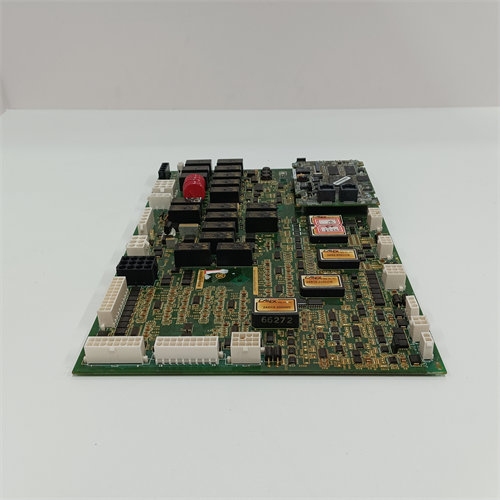

The GE IS200TRTDRTD is a component of the General Electric Mark VI (MK6) control system, which is used predominantly in industrial applications such as gas and steam turbine controls. This specific terminal board plays a vital role in the trip relay termination process.

Overview of GE IS200TRTDRTD

- Model: IS200TRTDRTD

- Type: Terminal Board

- Function: This board is designed for the termination of trip relay signals in the control system, serving as an interface between the control system and various field devices or safety mechanisms.

Key Features

- Trip Relay Termination:

- The IS200TRTDRTD board provides a structured and organized way to terminate trip relay connections, ensuring that signal paths to safety and alarm systems are effectively managed.

- Signal Conditioning:

- It may include circuitry to safeguard signals being transmitted, helping mitigate electrical noise and ensuring reliable communication with other system components.

- Ease of Installation:

- The board typically features clearly labeled terminals, making it straightforward for technicians to connect and disconnect wires as needed during installation and maintenance.

- Robust Design:

- Built to handle the demanding conditions of industrial environments, the board is often engineered for durability and reliability.

- Electrical Isolation:

- The design provides electrical isolation between the control circuitry and the external components, which helps to protect sensitive electronic systems from electrical faults.

Applications

The IS200TRTDRTD terminal board is commonly utilized in various contexts, including:

- Turbine Control Systems: It plays a critical role in managing shutdown criteria and ensuring that trip signals reach the appropriate safety devices.

- Industrial Automation Systems: Often integrated within broader automation frameworks to maintain effective control and safety measures.

- Safety and Alarm Management: Facilitates the connection of alarms and safety systems that respond to abnormal operational conditions.

Troubleshooting and Maintenance

To ensure the IS200TRTDRTD operates correctly, follow these troubleshooting and maintenance guidelines:

- Visual Inspection:

- Check for any signs of physical damage, such as burnt traces or loose connections, which could indicate operational issues.

- Power Supply Verification:

- Ensure that the terminal board is receiving the correct voltage and that all connections are properly secured.

- Connection Checks:

- Confirm that all terminal connections are tight and free from corrosion.

- Signal Testing:

- Use diagnostic equipment, like multimeters, to test for signal passage and integrity.

- Consult Technical Documentation:

- Reference manuals and schematics related to the IS200TRTDRTD for specific guidance on wiring and operation.

- Isolate the Board:

- If issues arise, consider testing the board in isolation from the larger system to determine whether the problem originates from the board itself or from external factors.

- Replacement Consideration:

- If troubleshooting does not resolve the issue, it may be necessary to replace the terminal board to restore normal operation.

Technical Support

For further information, technical specifications, or support regarding the GE IS200TRTDRTD terminal board, it’s advisable to consult GE’s technical support or refer to relevant documentation associated with the Mark VI control system. They can offer insights tailored to your specific operational context.

If you have any more questions or need further assistance, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922