الوصف

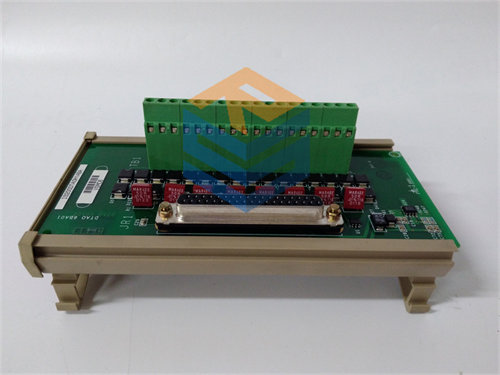

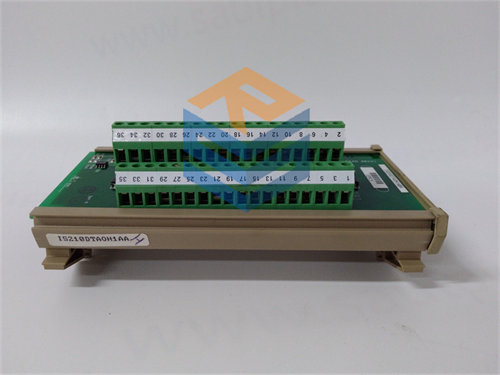

The GE IS200VCRCH1B is a specific model of Relay Control Board (VCRCH) in the GE Mark VI control system. This module is used for various control and monitoring functions in industrial environments, particularly in applications such as power generation.

Key Features:

- Relay Control:

- The IS200VCRCH1B includes multiple relay outputs that can be used to control external devices and systems based on operational conditions. This is critical for executing control commands such as turning equipment on or off.

- Contact Inputs:

- The board is equipped to receive multiple contact inputs, allowing it to monitor the status of various sensors and switches. This feedback capability enables the control system to respond dynamically to changing conditions.

- Signal Processing:

- The module processes input signals to determine the appropriate control actions, providing real-time responses to system events.

- Integration:

- As part of the Mark VI series, the VCRCH1B efficiently integrates with other control modules, enhancing overall system functionality. Communication with other components allows for coordinated operation in complex control scenarios.

- Durable Construction:

- Designed to operate in harsh industrial environments, the IS200VCRCH1B features a rugged construction that ensures reliability and longevity.

Applications:

The IS200VCRCH1B is commonly used in:

- Gas and steam turbine control systems, where precise control of relays is essential.

- Industrial automation applications requiring robust relay and monitoring capabilities.

- Systems where it is crucial to interface with various sensors and actuators for real-time monitoring and control.

Installation and Maintenance:

- Installation:

- Careful installation is vital for the proper operation of the IS200VCRCH1B. It should be mounted in a suitable chassis, and all electrical connections must be made according to the manufacturer’s specifications.

- Maintenance:

- Regular maintenance should include inspecting connections, testing relay operations, and ensuring input readings are accurate. It is advisable to run diagnostic checks periodically to identify any potential issues before they impact system operation.

Technical Documentation:

For detailed information regarding installation, wiring diagrams, operational guidelines, and troubleshooting procedures related to the IS200VCRCH1B, refer to GE’s official documentation for the Mark VI control system. This documentation is essential for ensuring proper setup and ongoing maintenance.

If you have specific questions or require more detailed information about the IS200VCRCH1B or its functionality, please let me know!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922