الوصف

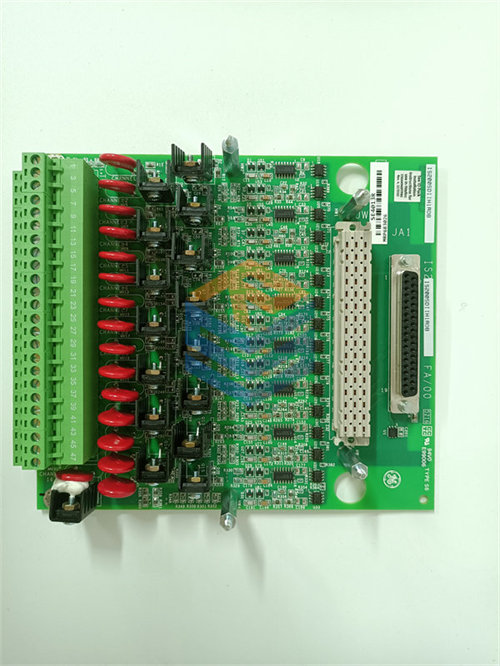

The GE IS200VCRCH1BBB is a specific model of a circuit board assembly within the GE Mark VI control system, which is widely used in industrial applications, particularly in turbine control for power generation. Here’s an overview of the IS200VCRCH1BBB, including its features, applications, installation, and maintenance.

Key Features of IS200VCRCH1BBB:

- Relay Outputs:

- The IS200VCRCH1BBB is equipped with multiple relay outputs that can activate or deactivate various external devices, such as motors, alarms, and other machinery. This capability is essential for implementing control strategies based on operational conditions.

- Contact Inputs:

- The board supports several contact inputs from external sensors and switches, allowing it to monitor the state of these devices. This feedback mechanism is critical for dynamic control.

- Signal Processing:

- The module processes input signals to determine the appropriate actions for controlling the relays based on specified logic, enhancing control and responsiveness in real-time system operations.

- Integrated Operation:

- As part of the Mark VI control system, the IS200VCRCH1BBB works in conjunction with other control modules, allowing for coordinated actions and communication across the system. This integration improves overall system performance.

- Durability:

- Constructed to endure harsh industrial environments, the IS200VCRCH1BBB features a robust design that ensures reliable operation and longevity, even under demanding conditions.

- Customization:

- Users may have the ability to customize the relay operations and input monitoring configurations based on specific requirements, making the board flexible for a variety of applications.

Applications:

The IS200VCRCH1BBB is commonly found in:

- Gas and steam turbine control systems in power plants.

- Industrial automation and control systems where effective relay management and monitoring are necessary.

- Applications that require reliable input/output operation in response to system parameters.

Installation and Maintenance:

- Installation:

- It is crucial to follow the manufacturer’s installation guidelines when setting up the IS200VCRCH1BBB. Ensure secure mounting in a compatible chassis and make precise electrical connections to minimize the risk of faults.

- Maintenance:

- Regular maintenance is necessary to ensure the longevity and reliability of the circuit board. This includes:

- Inspecting relay operations and replacing any faulty relays.

- Checking and securing all connections.

- Conducting routine diagnostics to identify and remedy potential issues.

- Keeping the board free from dust and debris.

- Regular maintenance is necessary to ensure the longevity and reliability of the circuit board. This includes:

Technical Documentation:

For detailed information on installation, wiring diagrams, operational procedures, and troubleshooting for the IS200VCRCH1BBB, it is important to consult the official GE documentation related to the Mark VI control system. This documentation will provide essential insights for effective implementation and ongoing maintenance.

If you have more specific questions or need further assistance regarding the IS200VCRCH1BBB circuit board assembly, please let me know!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922