الوصف

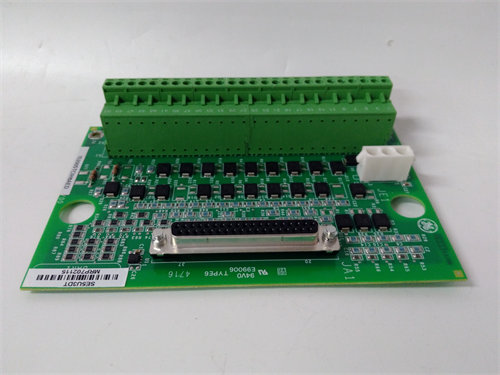

The GE IS200VPYRH1B is a VME Pyrometer Card for the Mark VI series of GE’s Speedtronic Gas Turbine Control Systems. This specialized board, often called a VPYR card, is designed to interface directly with pyrometers to monitor the temperature of critical components, particularly the turbine blades.

Key Features and Functionality

The IS200VPYRH1B provides a high-speed, reliable interface for non-contact temperature measurement, which is crucial for turbine health and performance. Here’s a breakdown of its primary functions:

- Pyrometer Interface: The card is specifically engineered to receive and process signals from multiple pyrometer sensors. Pyrometers are non-contact sensors that measure the temperature of an object by detecting its emitted thermal radiation. They are used to measure the temperature of turbine blades, which is a critical parameter for preventing overheating and mechanical failure.

- High-Speed Data Acquisition: The VPYR card is capable of high-speed data acquisition. Turbine blades rotate at thousands of revolutions per minute, so the sensor can only “see” each blade for a very short period. The VPYR card’s high sampling rate ensures that it can capture accurate temperature readings from each blade as it passes by.

- Dedicated Processor: The card has a dedicated on-board processor that handles the complex signal processing and calculations required for pyrometry. This offloads the intensive computational task from the main Mark VI controller, ensuring that the control system’s performance remains unaffected.

- VMEbus Interface: The card is designed to plug directly into the VME backplane of a Mark VI rack. This allows for high-speed communication with the main controller and other VME cards in the system.

- Diagnostics: The board’s faceplate typically features LED indicators to display its operational status, including power, run status, and fault alerts, making it easier to troubleshoot.

Technical Specifications

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922