الوصف

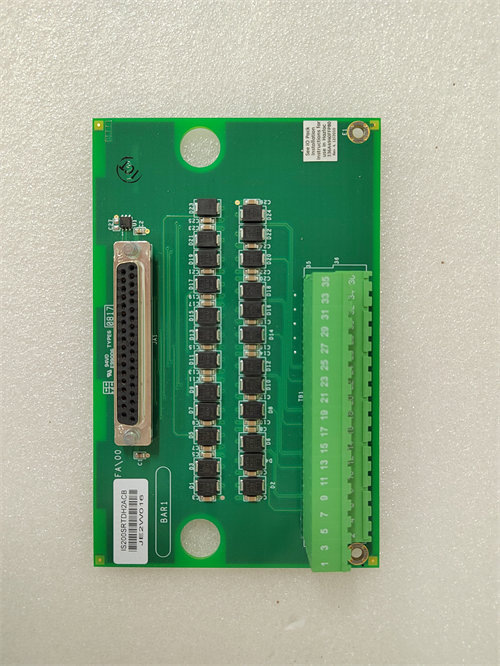

The GE IS200VRTD is a VME RTD (Resistance Temperature Detector) card used in various industrial control systems, particularly in the GE Mark VI and Mark VIe series of turbine control systems. Here are some key features and details about the IS200VRTD card:

Key Features:

- RTD Inputs: The IS200VRTD card can accept inputs from multiple RTD sensors, which are commonly used for temperature measurement in industrial applications.

- Signal Conditioning: The card includes circuitry to condition the signals from the RTDs, ensuring that they are suitable for processing by the control system.

- VMEbus Interface: As a VME card, it interfaces with other components in the control system over the VMEbus architecture.

- Data Acquisition: It is designed for accurate data acquisition, providing precise temperature readings that can be used for monitoring and control.

- Diagnostics: The card often comes with built-in diagnostic capabilities to monitor the health of the RTD inputs and the card itself.

Applications:

- Used in power generation, oil and gas, and other heavy industrial applications.

- It helps in monitoring temperatures in critical areas of turbines and generators.

Additional Considerations:

- When dealing with any industrial control system components, it is important to refer to specific user manuals or technical documentation for installation, wiring diagrams, and configuration settings.

- Be aware of compatibility with the specific control system version you are using, as parameters may vary.

If you need specific information regarding installation, operation, or troubleshooting, please provide more details, and I’ll do my best to assist!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922