الوصف

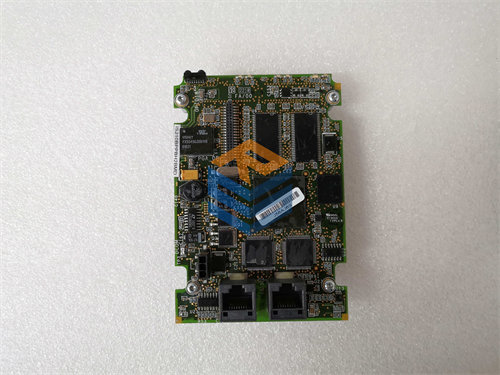

The GE IS210BPPBH2BMD is a Printed Circuit Board (PCB) module that is a component of GE’s Speedtronic Mark VI and Mark VIe turbine control systems. It plays a role in the control and monitoring of gas turbines, steam turbines, and other industrial turbines.

Based on available information, it’s described as a small auxiliary board that connects to a larger “WETA board” and is often associated with a “Combustion Engine Card Module” in the Mark VI system. It contains various electronic components like transformers, transistors, an inductor coil, and crystal oscillators.

While the exact, highly specific function of this particular “BMD” variant is not always fully detailed in public descriptions (as it’s a sub-component), its broader role within the Mark VI/VIe system is to contribute to:

- Signal Conditioning and Processing: Handling signals from sensors and input devices (e.g., temperature, pressure, vibration) related to turbine operation.

- Control Logic Execution: Contributing to the execution of control algorithms that manage the turbine’s operation.

- Data Acquisition and Transmission: Collecting and transmitting data within the control system.

- Communication Interface: Supporting communication with other control modules (like I/O modules, processor modules) and potentially higher-level systems via industrial protocols.

- Protection Functions: Monitoring system status and potentially triggering protection mechanisms (like shutdowns or alarms) under abnormal conditions, although the primary protection often resides on dedicated protection processor boards (like the BPPB series from which this might derive its naming convention).

It is designed with an industrial-grade robust build to withstand harsh environments typical of power plants, including high temperature, high humidity, and vibration, ensuring high reliability and a long service life.

Part One: Optimized SEO Titles

- GE IS210BPPBH2BMD: Mark VI/VIe Turbine Control PCB Module

- IS210BPPBH2BMD GE: Auxiliary Printed Circuit Board for Speedtronic

- GE IS210BPPBH2BMD: Gas & Steam Turbine Control Component

- Buy IS210BPPBH2BMD: Genuine GE Mark VIe Board Spare Part

- IS210BPPBH2BMD for Sale: Enhancing Turbine System Reliability

- GE IS210BPPBH2BMD: Signal Processing for Industrial Turbines

- Mark VIe Board IS210BPPBH2BMD: Critical Control System PCB

- IS210BPPBH2BMD: Robust Auxiliary Module for GE Turbines

- GE IS210BPPBH2BMD: High-Performance Control System Integration

- IS210BPPBH2BMD PCB: Essential for Turbine Management

Part Two: Brief Product Description

The GE IS210BPPBH2BMD is a printed circuit board (PCB) module specifically designed for integration into GE Speedtronic Mark VI and Mark VIe turbine control systems. This auxiliary board supports the control and monitoring of gas and steam turbines by performing signal conditioning, data processing, and contributing to control logic execution. It features a robust, industrial-grade design for reliable operation in demanding power generation environments.

- Product Type: Printed Circuit Board (PCB) Module

- Manufacturer: General Electric (GE)

- Compatibility: GE Speedtronic Mark VI and Mark VIe Turbine Control Systems

- Primary Function: Auxiliary board for signal processing, control logic, and data handling within turbine control.

- Application: Gas Turbines, Steam Turbines, Industrial Turbines, Wind Turbine Control Systems (some sources mention).

Part Three: Detailed Product Description

When a colossal gas turbine spins up to generate megawatts of electricity, every microsecond of its operation is meticulously managed by a complex control system. At the heart of this intricate network are specialized electronic components, like the GE IS210BPPBH2BMD printed circuit board. This isn’t just a generic circuit board; it’s a precisely engineered piece of hardware, a “neural pathway” within the turbine’s “brain” – the GE Speedtronic Mark VI or Mark VIe control system – ensuring every parameter is monitored, and every command executed with unwavering precision.

I recall a troubleshooting scenario in a combined cycle power plant where subtle, intermittent issues were occurring with a gas turbine’s auxiliary systems. After extensive diagnostics, the problem was traced back to a specific component on a Mark VI I/O board. While the IS210BPPBH2BMD itself is an auxiliary board, it’s representative of the many sub-components that make these complex systems function. A seemingly small part can have a significant impact on overall system reliability and performance. Ensuring the integrity and proper functioning of every PCB, like the IS210BPPBH2BMD, is crucial for maintaining the high availability and efficiency demanded by modern power generation assets.

Integral to Speedtronic Turbine Control: The GE IS210BPPBH2BMD is a specialized PCB module that forms part of the sophisticated architecture of the GE Speedtronic Mark VI and Mark VIe control systems. These systems are renowned globally for their robust and deterministic control of gas and steam turbines. The “BPPB” in its nomenclature often refers to Backup Protection Processor Board families, suggesting that this auxiliary module might contribute to or interface with the protection aspects of the turbine control system. Its role involves:

- Signal Conditioning: It conditions raw electrical signals from various sensors (e.g., thermocouples, pressure transducers, speed probes) before they are processed by the main controllers. This often involves filtering noise, amplifying weak signals, and converting them into a usable format.

- Interfacing with Main Boards: It connects to larger, primary control boards within the system, like the “WETA board” (which often refers to a Winding Earth Fault Protection board or similar high-density I/O/processor board in GE systems), extending their capabilities or providing specialized sub-functions.

- Data Flow and Processing: It helps manage the flow of data related to specific turbine operations and performs localized processing that offloads the main CPU, contributing to the overall real-time performance of the control system.

- Component of a Larger System: It’s not a standalone controller but rather a vital support component that ensures the integrity and functionality of the entire turbine control and monitoring ecosystem.

Robust Design for Demanding Environments: Given its application in power generation, the IS210BPPBH2BMD is built to exceptionally high industrial standards. This includes:

- Industrial-Grade Components: Populated with transformers, transistors, inductors, and crystal oscillators designed for long-term reliability in harsh conditions.

- Environmental Resilience: Capable of operating across wide temperature ranges (e.g., -40°C to +85°C for similar GE boards) and enduring high humidity, vibration, and electromagnetic interference (EMI).

- Quality Control: As a genuine GE part, it benefits from the rigorous testing and quality assurance processes essential for critical power plant equipment.

Potential Application in Wind Turbine Control: While primarily associated with gas and steam turbines, some sources indicate its use in GE wind turbine control systems. This highlights its versatility and the commonality of certain control philosophies and hardware components across different power generation platforms within GE’s portfolio. In this context, it would perform similar signal conditioning and control support functions relevant to wind turbine operation.

Technical Specifications (Based on common information for similar GE Speedtronic PCBs; specifics for IS210BPPBH2BMD should be confirmed with an official GE datasheet or manual):

Key Applications:

The GE IS210BPPBH2BMD is deployed in critical power generation and industrial settings:

- Gas Turbine Power Plants: For regulating fuel flow, combustion, speed, and overall turbine operation.

- Steam Turbine Power Plants: Controlling steam pressure, temperature, and turbine speed.

- Combined Cycle Power Plants: Integrating control across gas and steam turbine units.

- Industrial Turbine Applications: For various industrial processes that utilize turbines for power or mechanical drive.

- Wind Turbine Control: (As indicated by some sources) Potentially used in the control system of GE wind turbines for specific auxiliary functions related to power generation or pitch control.

Related Products:

As a component of the GE Mark VI/VIe system, the IS210BPPBH2BMD would be used alongside:

- GE Mark VI/VIe Controllers (CPUs/Processors): The main control processors that execute the core turbine control algorithms (e.g., IS215UCVEH2A, IS220UCVAH1A).

- GE Mark VI/VIe I/O Packs/Modules: Various input/output modules that connect directly to field devices (sensors, actuators) and interface with the main controllers (e.g., IS200 series I/O packs, IS420 series).

- GE Mark VI/VIe Cabinets and Racks: The physical enclosures and backplanes that house the control system components.

- GE ToolboxST Software: The engineering and diagnostic software used to configure, program, and troubleshoot the Mark VI/VIe system.

- HMI/Operator Interfaces: Workstations and software (like GE Cimplicity) that allow operators to monitor and interact with the turbine.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922