الوصف

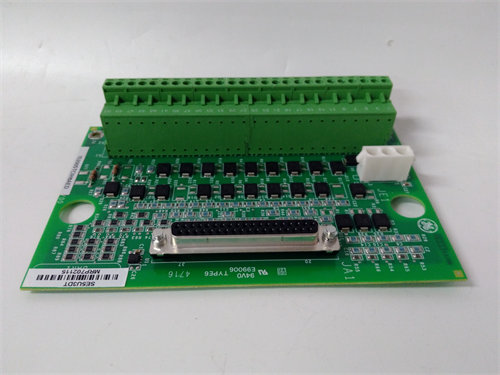

The GE IS210TTSAG1A is a Trip Servo Terminal Board Assembly for the Mark VIe series of GE’s Speedtronic Gas Turbine Control Systems. It is a critical component that interfaces the control system with the turbine’s trip servo valves, which are responsible for the controlled shutdown of the turbine. The TTSA in the part number stands for Trip Terminal Servo Assy.

Key Features and Functionality

The IS210TTSAG1A is vital for the safety and reliable operation of a turbine. Its main functions include:

- Servo Valve Interface: This board provides the physical connection points for the electro-hydraulic servo valves that control the fuel or steam flow to the turbine. These servo valves are used for precise positioning and are also essential for a controlled shutdown.

- Trip Logic Interface: It receives the trip command signals from the main Mark VIe controller. When a trip condition is met (e.g., overspeed), the board de-energizes the trip relays, which in turn causes the servo valves to move to a closed position, shutting off the fuel or steam.

- Signal Conditioning: The board conditions the signals from the controller to the servo valves. This includes converting the control signals into the precise current or voltage required to operate the valves, and also providing feedback signals from the valves back to the controller.

- Fail-Safe Design: The board is designed to be fail-safe, meaning that in the event of a power failure or a command to trip, the board will cause the servo valves to move to a safe, closed position.

- DIN-Rail Mounting: The assembly is designed for DIN-rail mounting, which is a common and efficient method for organizing and installing control system components in a cabinet.

- Application: This board is used in safety-critical applications where a reliable and fast shutdown is required to protect the turbine from catastrophic damage. It is a key part of the turbine’s emergency shutdown system.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922