الوصف

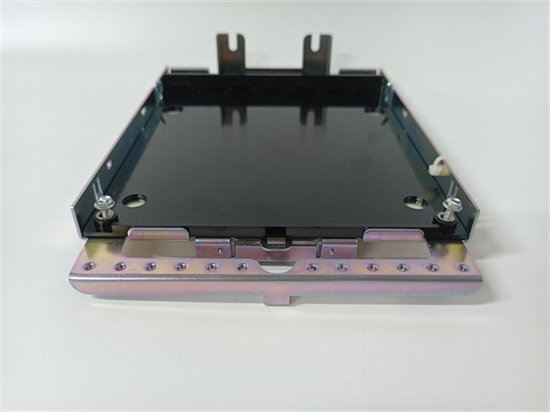

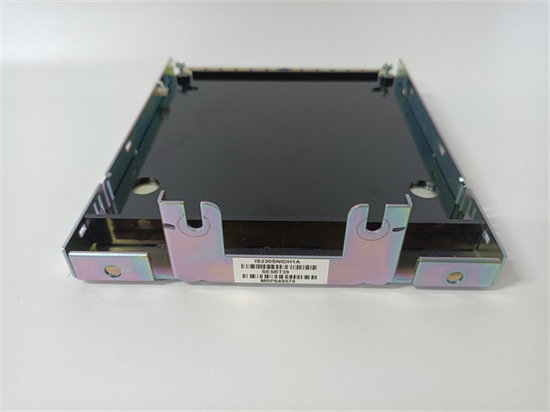

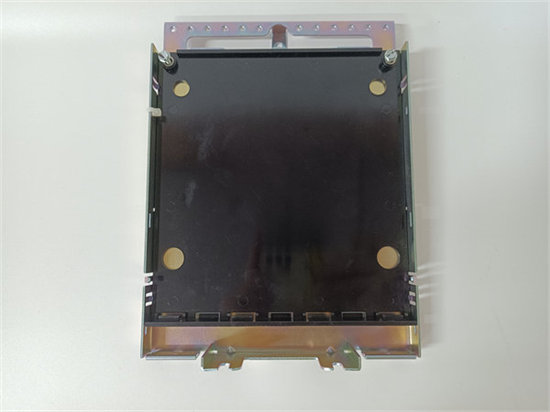

The GE IS215PMVPH1A is an Interface Board for the Mark VIe series of GE’s Speedtronic Gas Turbine Control Systems. It’s a specialized module that provides an interface for protective I/O signals. The PMVP in the part number stands for Pack Mounted Variable Protection, and the <P> indicates its primary function is for protective inputs and outputs.

Key Features and Functionality

The IS215PMVPH1A is a crucial component for the safety and protection system of a turbine. Its main functions include:

- Protective I/O Interface: The board is specifically designed to handle safety-critical signals. This includes inputs from devices like overspeed detectors, vibration sensors, or emergency stop buttons, and outputs to devices like trip relays and shutdown solenoids.

- Safety-Rated Design: The “Protection” designation signifies that this board is built to a higher level of reliability and integrity than a standard I/O board. It’s part of the overall safety instrumented system (SIS) and is designed to ensure that the turbine will trip or shut down when a hazardous condition is detected.

- Modular Mounting: As a “Pack Mounted” board, it is designed to be installed directly into an I/O pack, which simplifies wiring and reduces the overall footprint in the control cabinet.

- Signal Conditioning: It includes built-in circuitry to condition the protective signals, ensuring they are accurately read and that the outputs are reliably delivered to the safety devices.

- Application: This board is used in critical applications where a reliable and fast shutdown is required to protect the turbine from catastrophic damage, such as overspeed events or high vibration.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922