الوصف

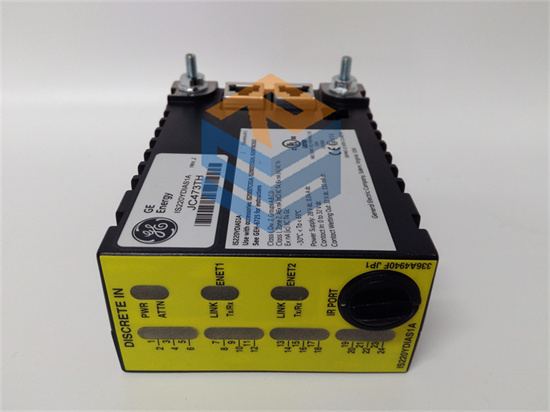

The GE IS215UCVEM01A is a part of General Electric’s Mark VI control system utilized in various industrial applications, particularly in gas and steam turbine management. This board operates on the VMEbus platform and is specifically designed for advanced communication and control features.

Key Features of GE IS215UCVEM01A:

- Enhanced Communication: As indicated by the 2ND ETHERNET designation, the IS215UCVEM01A supports an additional Ethernet port, which allows for improved communication capabilities between various components of the control system. This is particularly beneficial in environments requiring high data throughput and network redundancy.

- VME Interface: The card is designed to function within the VMEbus architecture, enabling modularity and flexibility in system designs. This allows users to integrate it seamlessly with other VME-based control modules.

- Data Acquisition and Processing: The IS215UCVEM01A provides sophisticated data processing capabilities, allowing it to collect and analyze information from multiple sensors and devices. This enhances the monitoring and operational efficiency of industrial processes.

- Industrial Control Applications: This controller card is particularly valuable in applications where reliable and efficient control of machinery is necessary. Its features support the management of turbines and other complex systems, ensuring optimal performance and safety.

- Built-in Diagnostics: The module usually includes diagnostic capabilities that allow for real-time monitoring and troubleshooting, helping operators to maintain system integrity and performance.

Applications:

The GE IS215UCVEM01A is typically used in:

- Turbine Control Systems: It plays a critical role in controlling gas and steam turbines, ensuring they operate efficiently and safely.

- Distributed Control Systems (DCS): It contributes to larger DCS applications by enabling communication between various control modules and field devices.

- Process Automation: The board is suitable for various industrial processes, offering the ability to automate and optimize operations effectively.

Maintenance and Troubleshooting:

- Regular Diagnostics: Use the built-in diagnostics to monitor the board’s operational status and preemptively address any anomalies.

- Consult Technical Documentation: Always refer to GE’s technical manuals for detailed instructions on installation, configuration, and maintenance of the IS215UCVEM01A.

- Firmware Management: Ensure that the firmware is kept up to date to maintain optimal performance and security.

Conclusion:

The GE IS215UCVEM01A board, with its additional Ethernet functionality, enhances the capabilities of the Mark VI control system, making it a key component in maintaining efficient industrial operations. Users can ensure reliable performance through regular upkeep and by leveraging GE’s technical resources.

If you have further questions or need more specific information about the IS215UCVEM01A and its applications, feel free to ask!

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922