الوصف

Here’s a detailed overview of the GE IS215UCVFH2BB module and its relevant specifications:

Product Name:

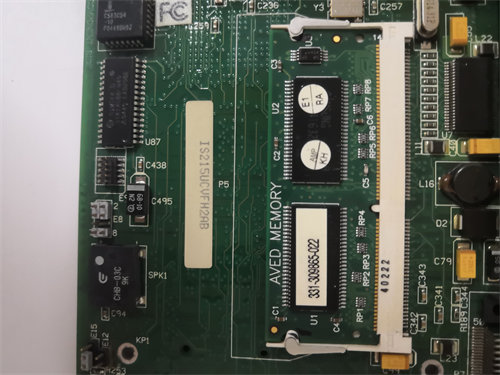

- Model Name: GE IS215UCVFH2BB

- Part Numbers: VMIVME-7650-83H, 350-007650-83H C

- Product Type: DCS/PLC Module (Part of the Mark VIe or Mark VI Distributed Control System)

Product Description:

The GE IS215UCVFH2BB is an advanced Universal Controller module designed to be integrated into GE’s Mark VIe and Mark VI Distributed Control System (DCS). The module serves a critical role in process automation by providing a high-performance controller for managing and controlling industrial processes in applications such as power generation, chemical processing, and oil & gas.

This module is part of the Mark VIe Control System family, which is known for its scalability, flexibility, and reliability in mission-critical industrial environments. The IS215UCVFH2BB is specifically designed for process control, monitoring, and automation and is equipped with high-speed I/O, powerful processing capabilities, and support for a wide range of communication protocols.

The module can handle a variety of analog and digital signals from field devices, allowing it to interface with sensors, actuators, and other control equipment. Its architecture is modular, meaning it can be expanded to meet the requirements of large-scale industrial plants.

Key Features:

-

Universal Controller: The IS215UCVFH2BB serves as a flexible and high-performance controller for industrial automation systems.

-

Advanced Communication: It supports Ethernet, Modbus, Profibus, and other common industrial communication protocols for easy integration with other systems.

-

Real-Time Monitoring and Control: Provides real-time data collection and processing for control applications, ensuring continuous operation of critical systems.

-

Modular Design: Its modularity allows easy scaling and upgrading of the system by adding additional I/O modules, controllers, and communication networks.

-

Reliability and Redundancy: Built with high redundancy options, making it suitable for mission-critical applications that require high uptime and fault tolerance.

-

Diagnostic Features: The module includes self-diagnostic tools to assist in identifying issues or faults and reducing downtime.

Product Parameters:

-

Type: Universal Controller (UC) module for Mark VIe DCS.

-

Input/Output Support: Supports various types of inputs and outputs, including analog, digital, and relay outputs.

-

Signal Types: Typically interfaces with 4-20 mA, 0-10V analog inputs, and dry contact digital signals.

-

Processor Type: High-performance microprocessor-based system capable of executing complex control algorithms and managing extensive I/O operations.

-

Data Storage: Includes non-volatile memory for storing configuration data, operational parameters, and logs.

-

Communication Protocols:

- Ethernet/IP

- Modbus TCP/IP

- Profibus DP

- Serial communication (RS-232/RS-485)

-

Power Supply Requirements: Typically operates with a 24V DC power supply.

-

Environmental Conditions:

- Operating Temperature: Ranges from 0°C to 60°C.

- Storage Temperature: Ranges from -40°C to 85°C.

- Humidity: Operating humidity levels typically 5% to 95% non-condensing.

Product Specifications:

-

I/O Channels:

- Number of I/O Channels varies depending on specific system configuration (could support analog, digital, or relay-based I/O channels).

- Configurable inputs for both analog (e.g., 4-20 mA, 0-10V) and digital signals (e.g., dry contacts, pulse).

-

Processor and Memory:

- Processor: Advanced multi-core processors capable of fast decision-making and real-time control tasks.

- Memory: Includes both volatile and non-volatile memory for program storage, logs, and runtime data.

- RAM/Flash Memory: Typically features 4MB to 8MB of RAM for real-time processing and additional 32MB to 64MB of flash memory for system storage.

-

Redundancy:

- Supports redundant controllers, ensuring continuous system operation in case of a failure. This is essential in critical industrial environments that require zero downtime.

- Redundant power supplies are also available for increased system reliability.

-

User Interface and Configuration:

- Can be configured and monitored via GE’s proprietary software tools, such as ControlST or PlantST, using a user-friendly graphical interface.

- Remote access for monitoring and control is also supported through secure communication networks.

-

Safety Features:

- Designed to meet international safety standards and certifications, such as UL, CE, and IEC.

- Built-in fault tolerance and diagnostics for real-time monitoring of system health.

-

Dimensions & Mounting:

- The module typically comes in a rack-mounted form factor suitable for 19-inch racks. Its size usually occupies 3U of rack space.

- Mounting is designed for easy integration into control panels or enclosures within industrial facilities.

-

Control Algorithms:

- Capable of handling complex control loops, including PID (Proportional-Integral-Derivative), feedforward control, and more specialized control algorithms for industrial processes.

-

Approvals and Certifications:

- The IS215UCVFH2BB is typically certified to meet industry standards and safety certifications, such as ATEX for hazardous environments (depending on configuration).

-

Redundant Communication Channels:

- Multiple communication paths are supported to ensure uninterrupted data transmission, including redundant Ethernet and serial communications.

Applications:

-

Power Generation: Used for managing generator control, turbine control, and boiler systems, ensuring optimal operation and safety.

-

Chemical Processing: Integrated into control systems for reactor control, distillation columns, and other process units requiring tight control of variables like temperature, pressure, and flow.

-

Oil & Gas: Employed in pump control, valve control, and wellhead automation, ensuring efficient operation of oil and gas facilities.

-

Water Treatment: Utilized for managing pumps, filtration systems, and chemical dosing systems in water treatment plants.

-

Manufacturing: Integrated into assembly lines, robotic control systems, and packaging systems for high-efficiency manufacturing processes.

Conclusion:

The GE IS215UCVFH2BB module is a high-performance universal controller designed for use in GE’s Mark VIe DCS. It provides flexible, scalable, and reliable control and monitoring of industrial processes, making it ideal for power generation, chemical, and oil & gas industries. Its advanced communication capabilities, diagnostic tools, and redundant features make it suitable for mission-critical applications that require high reliability, real-time control, and fault tolerance. The modular design of the IS215UCVFH2BB allows for easy integration and expansion to meet the needs of complex industrial systems.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922