الوصف

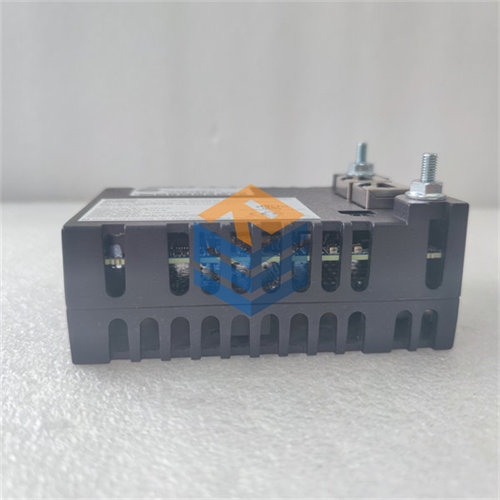

The GE IS230SNCIH4A is a digital input module for the GE Mark VIe control system. This module is designed to be mounted on a DIN rail and is used to read discrete, or on/off, signals from various field devices.

Key Features

- Digital Input: The module’s primary function is to handle binary signals that represent a two-state condition (e.g., a switch is either open or closed, a push-button is either pressed or released). It acts as a bridge between the physical world and the control system’s digital logic.

- DIN Rail Mounting: The module is built for standardized installation on a DIN rail, which is a common practice in industrial control cabinets. This simplifies wiring, saves space, and makes installation and maintenance more efficient.

- Mark VIe Integration: The “IS230” prefix confirms that this module is part of the Mark VIe series. It integrates seamlessly with the system’s main controllers, ensuring reliable communication and data processing.

Applications

The IS230SNCIH4A is used in various industrial settings where reliable monitoring of on/off signals is required.

- Power Generation: It’s used to monitor the status of devices on gas and steam turbines, such as valve limit switches, motor run/stop indicators, and pressure switches.

- Oil and Gas: In refineries and offshore platforms, it helps monitor the open/closed status of valves, the status of pumps, and the state of emergency push-buttons.

- Industrial Automation: The module is a fundamental component in many manufacturing processes that rely on automated control for efficiency and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922