الوصف

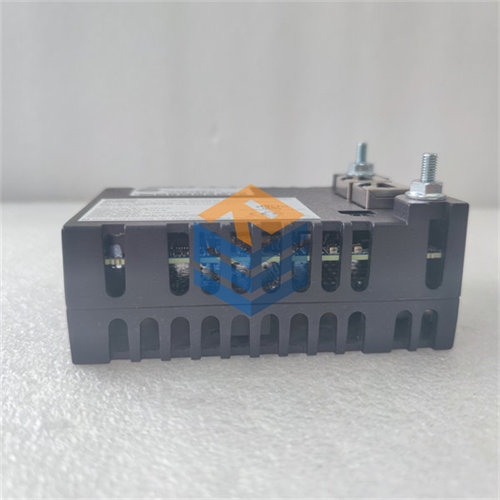

The GE IS230SNTCH4A is a thermocouple input module assembly for the GE Mark VIe control system. It’s an assembly that combines a STTCH2A terminal board with a PTCCH2B I/O pack. The module’s purpose is to accurately measure temperature from thermocouples and transmit that data to the controller.

Key Features

- Thermocouple Input: This module is specifically designed to work with thermocouples, a common type of temperature sensor. It’s built to handle the very low voltage signals generated by thermocouples and includes features like cold junction compensation to ensure accurate temperature readings.

- PTCCH2B I/O Pack: This pack is the core of the assembly. It contains the electronics that process the signals from the thermocouples, convert them to a digital format, and perform diagnostics.

- STTCH2A Terminal Board: This board provides the physical connection points for the thermocouple wires, ensuring a secure and organized interface for installation.

- Mark VIe System Integration: As a component of the IS230 series, this assembly seamlessly integrates with the Mark VIe control platform, ensuring reliable and high-performance temperature monitoring.

Applications

The IS230SNTCH4A is vital in industrial settings that require precise and reliable temperature monitoring.

- Power Generation: It’s used in power plants to monitor critical temperatures on gas and steam turbines, such as exhaust gas temperatures and bearing temperatures, which are essential for safe and efficient operation.

- Oil and Gas: In refineries and offshore platforms, it measures temperatures in pipes, reactors, and furnaces, helping to ensure process safety and efficiency.

- Industrial Automation: It’s a fundamental component in many manufacturing processes where temperature control is critical for product quality and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922