الوصف

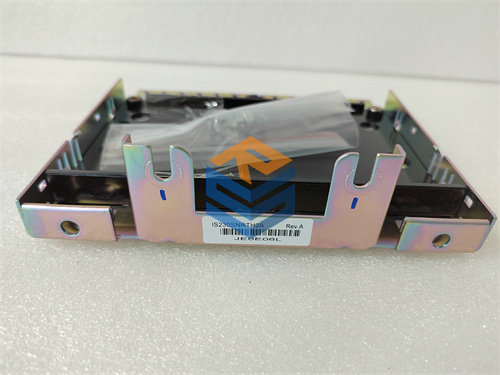

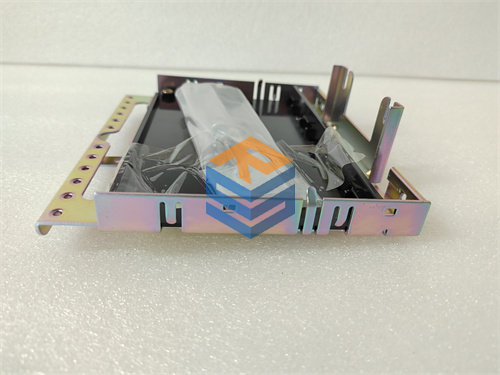

GE IS230TBAI1CG01 MKVIe, Analog I/O Assembly, TMR

The GE IS230TBAI1CG01 is a triple-modular redundant (TMR) analog I/O assembly for the GE Mark VIe control system. This module is specifically designed for high-reliability, safety-critical applications where uninterrupted operation is essential.

Key Features

- Analog I/O: The module handles both continuous analog inputs (from sensors like pressure and flow transmitters) and analog outputs (to devices like valves and actuators). This allows for both monitoring and controlling continuous process variables.

- TMR (Triple-Modular Redundant): This is the most important feature. The TMR configuration uses three identical modules operating in parallel. The system uses a voting algorithm to compare the outputs from the three modules, ensuring that the system can continue to operate and provide accurate data even if one or two modules fail.

- Mark VIe Integration: As part of the IS230 series, this assembly seamlessly integrates with the Mark VIe control platform, which is widely used in power generation.

Applications

The IS230TBAI1CG01 is used in industrial settings where the loss of an analog signal could lead to a catastrophic event or significant downtime.

- Power Generation: It is used in turbine control systems to monitor and control critical variables like fuel flow or pressure. The TMR configuration ensures that the turbine can continue to operate safely even if a module fails.

- Oil and Gas: In refineries and offshore platforms, it helps manage critical process variables with a high degree of reliability to prevent hazardous conditions. The redundancy is essential for maintaining control in a harsh environment.

- Process Safety: This module is a fundamental component in any process where a failure in monitoring or control could result in significant equipment damage or a safety risk.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922