الوصف

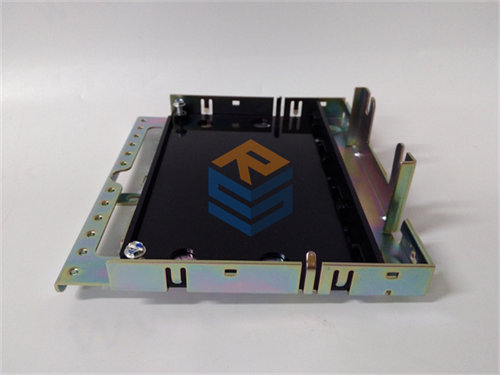

The GE IS230TBAIH1C is a basic analog I/O assembly for the GE Mark VIe control system. It operates in a simplex configuration, which means it’s a single, non-redundant unit, and is designed to handle both analog inputs and outputs.

Key Features

- Analog I/O: The module is designed to handle both analog inputs (receiving continuous signals from sensors like pressure and flow transmitters) and analog outputs (sending continuous signals to devices like valves and actuators). This allows for both monitoring and controlling continuous process variables.

- Simplex Configuration: The term “simplex” means the module is a single, non-redundant unit. This is a common and cost-effective solution for applications where a single point of failure won’t lead to a catastrophic event. It’s often used for less critical monitoring or control loops.

- Mark VIe Integration: As a core part of the IS230 series, this assembly is designed to seamlessly integrate with the Mark VIe control platform, ensuring a reliable interface between the physical process and the main controller.

Applications

The IS230TBAIH1C is used in various industrial settings that require reliable analog control and monitoring.

- Power Generation: It’s used in power plants to monitor and control continuous variables on gas and steam turbines, such as fuel flow rates, lubrication oil pressure, and valve positions.

- Oil and Gas: In refineries and offshore platforms, it helps manage critical process variables, including the level of fluids in tanks, pressure in pipelines, and the position of control valves.

- Industrial Automation: The module is a fundamental component in many manufacturing processes that rely on automated control for efficiency and product quality.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922