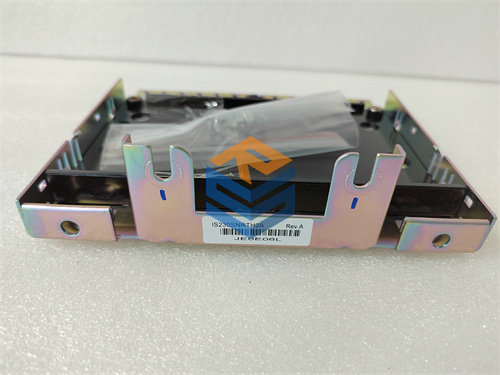

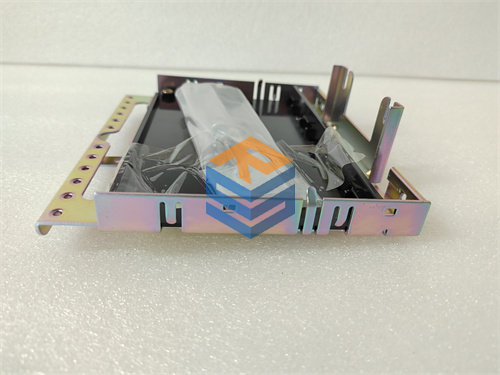

الوصف

The GE IS230TBAOH1C is an 8-channel analog output assembly for the GE Mark VIe control system. This module is used to send continuous, variable signals from the controller to a process, enabling precise control of equipment.

Key Features

- Analog Output: This module converts a digital command from the controller into an analog signal, typically a 4-20 mA current or a 0-10V voltage. This continuous signal is used to operate field devices, providing more precise control than a simple on/off signal.

- 8-Channel: The module can manage up to eight separate analog output signals, making it a versatile component for controlling multiple devices from a single unit.

- Mark VIe Integration: As a part of the IS230 series, this assembly is designed to integrate seamlessly with the Mark VIe platform. It works with the main controller and other system components to ensure accurate and reliable control.

Applications

The IS230TBAOH1C is a fundamental component in industrial settings that require precise and reliable process control.

- Power Generation: It’s used in power plants to control fuel flow, turbine speed, and the position of various valves to maintain stable and efficient operation of gas and steam turbines.

- Oil and Gas: In refineries and offshore platforms, it controls the position of critical valves to regulate flow, pressure, and temperature.

- Industrial Automation: It’s used in a wide range of manufacturing processes to control variables such as the speed of a conveyor belt, the pressure in a reaction vessel, or the temperature in a kiln.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922