الوصف

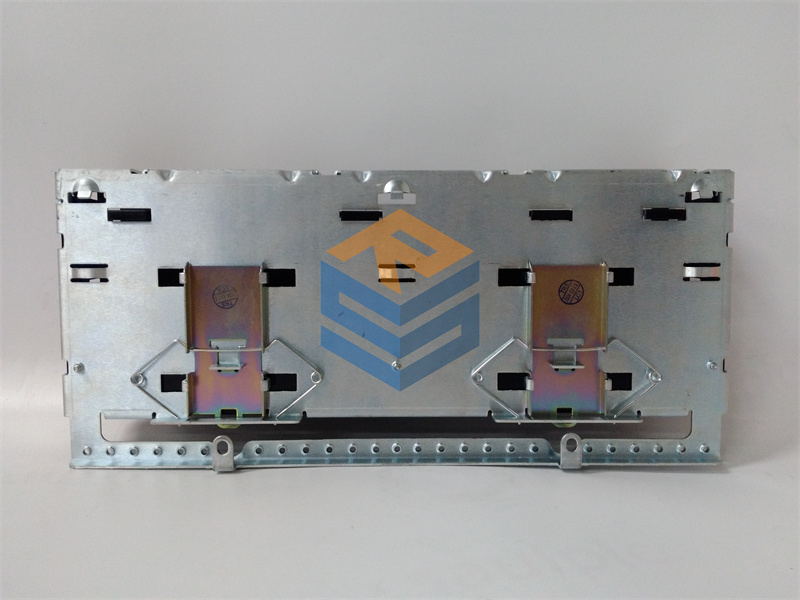

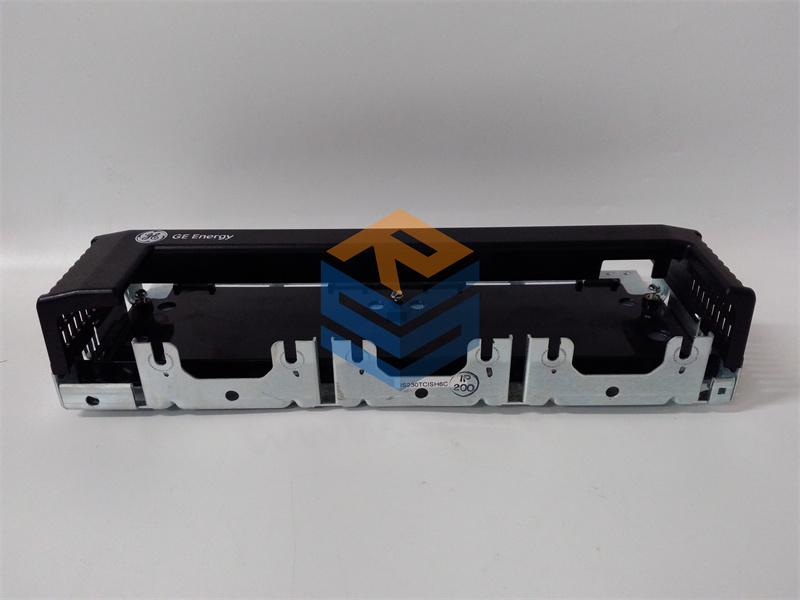

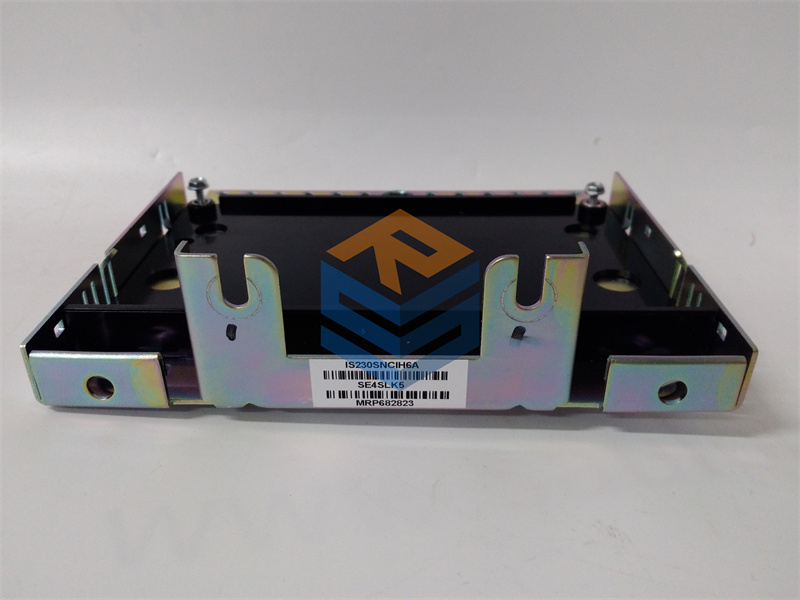

The GE IS230TBTCH1C is a triple-modular redundant (TMR) thermocouple input assembly for the GE Mark VIe control system. This module is specifically designed for high-reliability, safety-critical applications where uninterrupted temperature data is essential.

Key Features

- Thermocouple Input: The module is designed to read signals from thermocouples, which are common industrial temperature sensors. It accurately converts the small voltage from the thermocouple into a precise temperature value for the controller. It also includes built-in cold junction compensation to ensure accuracy.

- TMR (Triple-Modular Redundant): This is the most important feature. The TMR configuration uses three identical modules operating in parallel. The system uses a voting algorithm to compare the inputs from all three, ensuring that the control system receives the correct temperature reading even if one or two of the modules fail. This redundancy is a core component of the Mark VIe’s high-reliability architecture.

- Mark VIe Integration: This assembly is a key part of the Mark VIe platform, ensuring seamless integration and compatibility with the main controller. It provides the high-speed and reliable data acquisition needed for critical temperature loops.

Applications

The IS230TBTCH1C is vital in industrial settings where a loss of temperature data could lead to a catastrophic event.

- Power Generation: It is used in power plants to monitor critical temperatures on gas and steam turbines, such as exhaust gas temperatures and bearing temperatures. The TMR redundancy ensures continuous monitoring, which is essential for safe and efficient operation.

- Oil and Gas: In refineries and offshore platforms, it’s used to measure temperatures in pipes, reactors, and furnaces, helping to ensure process safety and efficiency. The redundant nature provides an extra layer of protection against unexpected failures.

- Critical Process Control: The module is a fundamental component in any process where a failure to monitor temperature could result in significant equipment damage or a safety risk.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922