الوصف

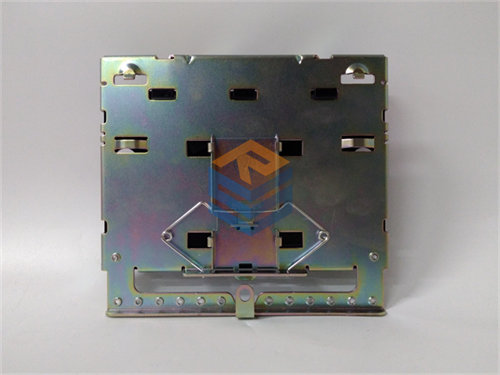

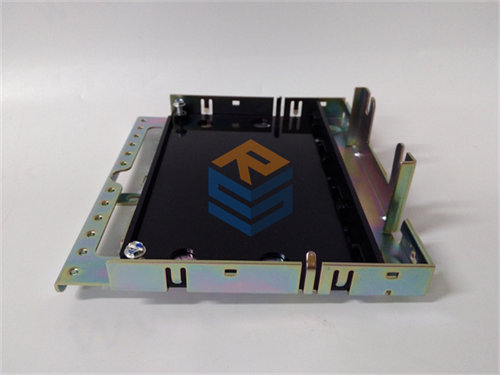

The GE IS230TBTCH5B is a simplex thermocouple input assembly for the GE Mark VIe control system. This module is used to read temperature signals from thermocouples, which are a common type of industrial temperature sensor.

Key Features

- Thermocouple Input: The module is specifically designed to work with thermocouples, which are sensors that generate a small voltage proportional to temperature. The module accurately reads this signal and includes built-in cold junction compensation to ensure the temperature measurement is precise and reliable.

- Simplex Configuration: The term “simplex” indicates a single, non-redundant unit. This is a common and cost-effective approach for applications where a single point of failure won’t lead to a catastrophic event. It’s often used for less critical temperature monitoring loops.

- Mark VIe Integration: As part of the IS230 series, this assembly is designed to seamlessly integrate with the Mark VIe control platform, ensuring reliable and high-performance temperature monitoring.

Applications

The IS230TBTCH5B is used in various industrial settings that require reliable temperature monitoring.

- Power Generation: It is used in power plants to monitor temperatures on gas and steam turbines, such as exhaust gas temperatures and bearing temperatures, which are essential for safe and efficient operation.

- Oil and Gas: In refineries and offshore platforms, it’s used to measure temperatures in pipes, reactors, and furnaces, helping to ensure process safety and efficiency.

- Industrial Automation: It’s a fundamental component in many manufacturing processes where temperature control is critical for product quality and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922