الوصف

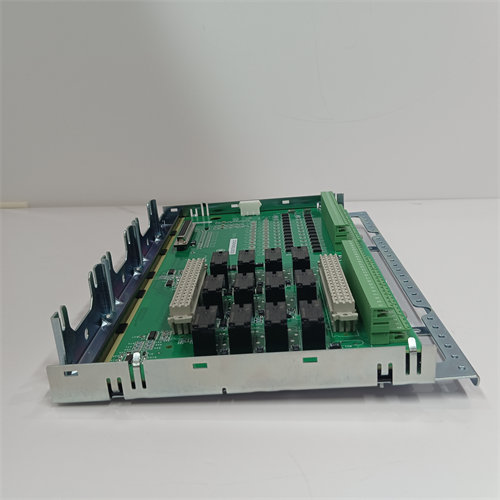

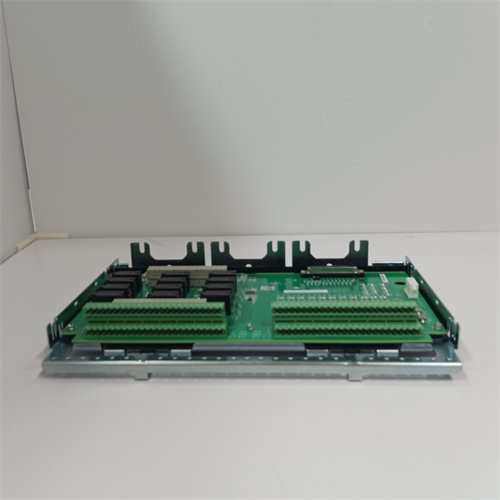

The GE IS230TCISH6CAX is a DIN rail-mounted I/O module for the GE Mark VIe control system, specifically certified for use in potentially explosive atmospheres as indicated by the ATEX certification. This module is a core component of a contact input assembly, designed to read binary (on/off) signals from field devices in a high-reliability, redundant configuration.

Key Features

- Contact Input: The module’s primary function is to handle binary signals from devices like switches and push-buttons. It acts as an interface that converts their physical state into a digital signal that the Mark VIe controller can understand.

- ATEX Certification: The “AX” in the part number indicates that the module is certified for use in potentially explosive atmospheres (e.g., zones with flammable gases, vapors, mists, or dust). This certification is critical for applications in the oil and gas, petrochemical, and power generation industries.

- DIN Rail Mounting: The module is built for standardized installation on a DIN rail, which is a common practice in industrial control cabinets. This simplifies wiring, saves space, and makes installation and maintenance more efficient.

- I/O Module: This is the electronic part of the I/O assembly, containing the circuitry that processes the signals. It works in conjunction with a terminal board (like the TBCI series) where the field wiring is terminated.

Applications

The IS230TCISH6CAX is used in a wide range of industrial settings where reliable monitoring of on/off signals is required, especially in hazardous environments.

- Power Generation: It’s used in power plants to monitor the status of devices on gas and steam turbines, such as valve limit switches, motor run/stop indicators, and pressure switches.

- Oil and Gas: In refineries and offshore platforms, it helps monitor the open/closed status of valves, the run/stop status of pumps, and the state of emergency push-buttons, with the ATEX rating being essential for these environments.

- Industrial Automation: The module is a fundamental component in many manufacturing processes that rely on automated control for efficiency and safety.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922