الوصف

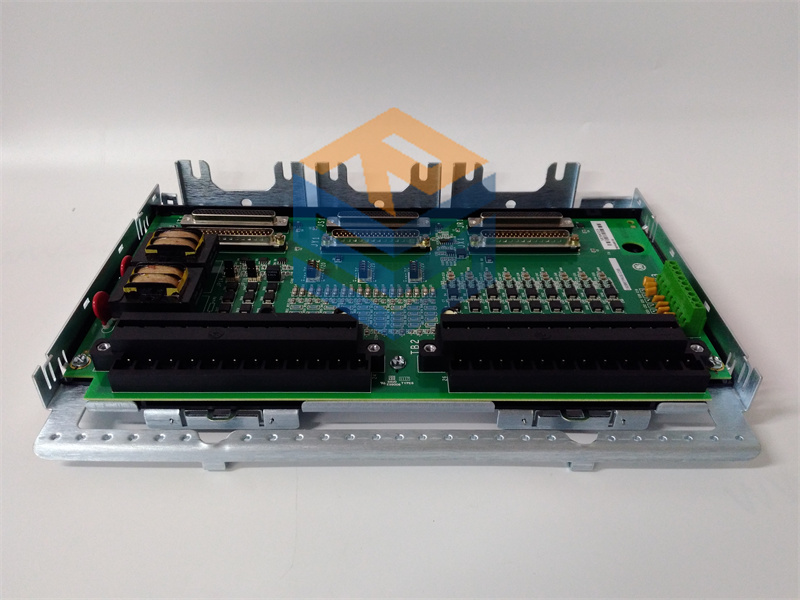

The GE IS230TNAIH2CAX is a DIN rail-mounted analog I/O module for the GE Mark VIe control system. The “AX” in the part number indicates that the module is certified for use in potentially explosive atmospheres as per ATEX standards.

Key Features

- Analog I/O: The module handles both continuous analog inputs (from sensors like pressure and temperature transmitters) and analog outputs (to devices like valves and actuators). This allows for both monitoring and controlling continuous process variables.

- ATEX Certification: The “AX” signifies that the module has been certified for safe operation in hazardous environments where flammable gases, vapors, mists, or dust may be present. This is a critical requirement for applications in the oil and gas, petrochemical, and power generation industries.

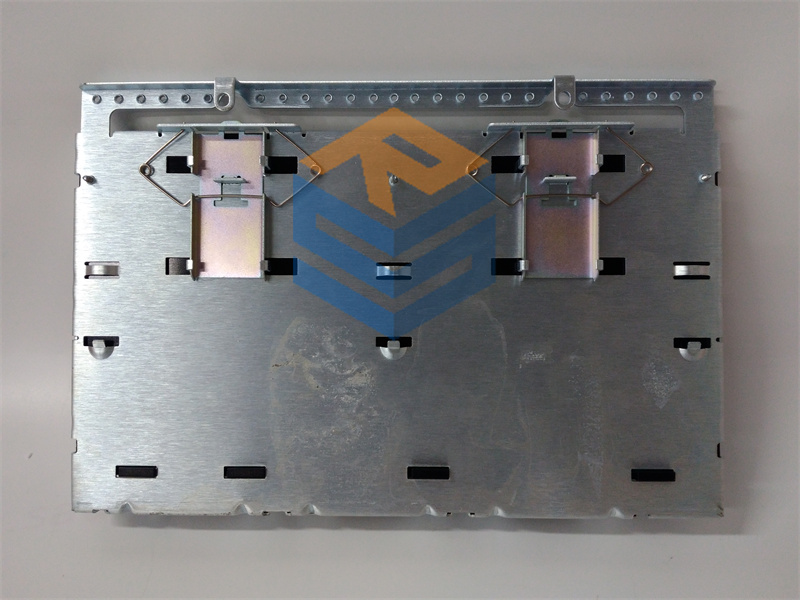

- DIN Rail Mounting: The module is designed for standardized installation on a DIN rail, which is a common practice in industrial control cabinets. This simplifies wiring, saves space, and makes installation and maintenance more efficient.

- I/O Module: This is the electronic part of the I/O assembly, containing the circuitry that processes the signals. It works in conjunction with a terminal board where the field wiring is terminated.

Applications

The IS230TNAIH2CAX is used in a wide range of industrial settings to provide a reliable interface between the physical process and the control system, especially in hazardous locations.

- Power Generation: It provides the I/O processing for various signals related to turbine operation, such as fuel flow rates and lubrication oil pressure. The ATEX rating is essential for applications involving natural gas turbines.

- Oil and Gas: In refineries and offshore platforms, it’s used to manage and process signals for pumps, valves, and other critical process equipment in hazardous areas where the ATEX certification is a safety requirement.

- Industrial Automation: It’s a fundamental building block in automated manufacturing processes that require precise and reliable control, particularly in chemical processing plants or other facilities with a risk of explosion.

+86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922